एसएसपी से ऑर्डर कैसे करें और संवाद कैसे करें

एसएसपी से ऑर्डर कैसे करें और संवाद कैसे करें। सटीक विनिर्माण की तेज़ गति वाली दुनिया में, प्रभावी

When it comes to manufacturing tools, understanding the true cost of tooling is essential for staying within budget. Have you ever wondered why tooling costs vary, especially when working with power tools manufacturers in China or hand tools manufacturers in China?

Tooling involves more than just production; it includes factors like tooling cost breakdown और amortization of tooling cost, which can significantly impact your bottom line. In this post, we’ll break down how to estimate and manage tooling costs effectively, focusing on tool manufacturing companies और tooling manufacturers in China. Whether you’re new to manufacturing or looking to optimize your costs, this guide will help you navigate the process efficiently without sacrificing quality.

When diving into the world of manufacturing, tooling costs are often one of the most significant expenses you’ll encounter. Whether you’re sourcing tools from tool manufacturing companies in China or other regions, understanding how these costs break down is key to managing your budget effectively. But what exactly makes up the tooling price, and why can it vary so widely from supplier to supplier?

In this section, we’ll walk you through the essentials of tooling costs and explain the factors that influence them. By the end, you’ll have a clearer picture of what to expect when planning your next manufacturing project.

What is Tooling?

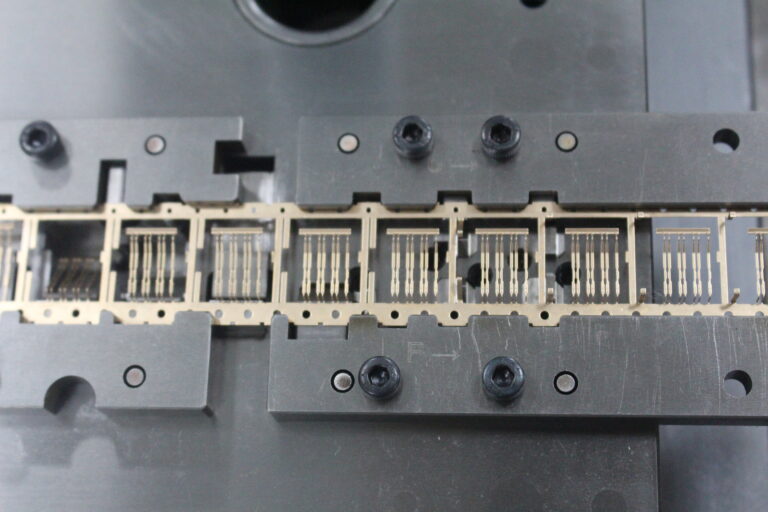

At its core, tooling refers to the specialized equipment, molds, and dies used to shape, form, and produce the final product. These tools are essential for creating parts with precision, whether you’re manufacturing power tools, automotive components, or consumer goods. The tooling process is what allows manufacturers to produce consistent, high-quality products at scale.

However, tooling isn’t a one-size-fits-all solution—it varies depending on the complexity of the design, the materials used, and the quantities involved. And while the upfront cost may seem high, tooling is an investment that sets the foundation for large-scale production.

Tooling costs are made up of several components that all contribute to the final price. Let’s break them down:

Factors That Affect Tooling Costs

Tooling costs are not static—they can fluctuate based on several factors, especially when you’re working with manufacturers in different regions. Let’s take a look at some key variables that affect the price:

How Tooling Costs Influence Your Manufacturing Budget

Tooling costs represent a large chunk of your initial investment, but they should be seen as an investment in your long-term production goals. Once the tooling is created, it can last for thousands, or even millions, of units, helping you scale production efficiently. However, these upfront costs must be balanced against the long-term gains in efficiency and product consistency.

When budgeting for tooling, consider both the amortization of tooling costs and the potential savings from larger production runs. While high-quality tooling can seem expensive initially, it can significantly reduce per-unit costs over time and result in a better product. Understanding this balance between tooling cost breakdown and production volume will help you make informed decisions that benefit both your budget and your product quality.

Tooling costs are a crucial factor in any manufacturing project, and understanding what goes into them can help you make more cost-effective decisions. Whether you’re working with tool manufacturing companies in China or local suppliers, it’s essential to grasp the breakdown of costs such as design, material, and production time. By doing so, you’ll be better prepared to optimize your budget.

The key is clear communication with your tooling manufacturers and a solid understanding of whether custom tooling or standard options are right for your needs. Can large production runs help reduce costs, or is a smaller, more precise order better suited for your project?

In the end, tooling is an investment in long-term quality and efficiency. By focusing on tooling cost estimation and managing the amortization of tooling cost, you can balance price and performance effectively. With the right knowledge and planning, you’ll be on your way to optimizing your manufacturing costs and ensuring a successful outcome for your business.

एसएसपी से ऑर्डर कैसे करें और संवाद कैसे करें। सटीक विनिर्माण की तेज़ गति वाली दुनिया में, प्रभावी

एसएसपी टूल विकास प्रक्रिया: उच्च गुणवत्ता और उपयोगकर्ता की जरूरतों को सुनिश्चित करना एक बार ऑर्डर के लिए