What Is Precision Metal Stamping dies? A Beginner’s Guide to Sheet Metal Manufacturing

SSP is well known Stamping die manufacturing services provider. Working in this sector for a decades .

lets learn about from the very best in the industry.

Brief of Stamping dies

Have you ever taken a moment to look closely at the metal parts in your phone, car, or even your kitchen appliances and wondered—how are these made with such exactness? You’re not alone. Behind almost every finely crafted metal part is a process that blends force, finesse, and incredible precision: precision metal stamping dies.

This isn’t just a buzzword manufacturers throw around. Precision stamping is a specialized method within sheet metal fabrication that helps shape complex metal parts quickly and with exceptional accuracy. And it’s a lot more fascinating than you might think.

Whether you’re new to the world of manufacturing or just curious about how everyday products come to life, this beginner’s guide is built for you. We’ll walk through the essential steps, key tools, and types of stamping processes—all while keeping things easy to follow and, more importantly, relevant to real-world applications.

Let’s get into it.

Understanding Precision Metal Stamping dies

You’ve probably heard the term “metal stamping” before, but what makes it precision metal stamping dies?

Picture this: a high-powered machine slamming down on a sheet of metal, cutting, forming, and shaping it into the exact component needed—down to fractions of a millimeter. That’s precision stamping in action.

At its core, this process transforms flat metal sheets into complex, detailed components by pressing them through custom-made dies. And unlike traditional stamping, where the margins for error are higher, precision stamping dies is engineered for consistency and accuracy—especially when parts need to be replicated thousands or even millions of times.

Why It Matters:

- Precision matters when your components are going into cars, aircraft, or electronics—where failure isn’t an option.

- It enables mass production without sacrificing quality.

- Parts come out clean, ready to assemble, and often require minimal post-processing.

Industries like automotive, electronics, aerospace, and medical manufacturing rely heavily on this process to deliver on tight tolerances and high safety standards

Key Components of the Stamping dies Process

Ever tried baking with the wrong size pan or the wrong ingredients? The same idea applies here. The tools and materials you use in precision stamping can make or break the final product.

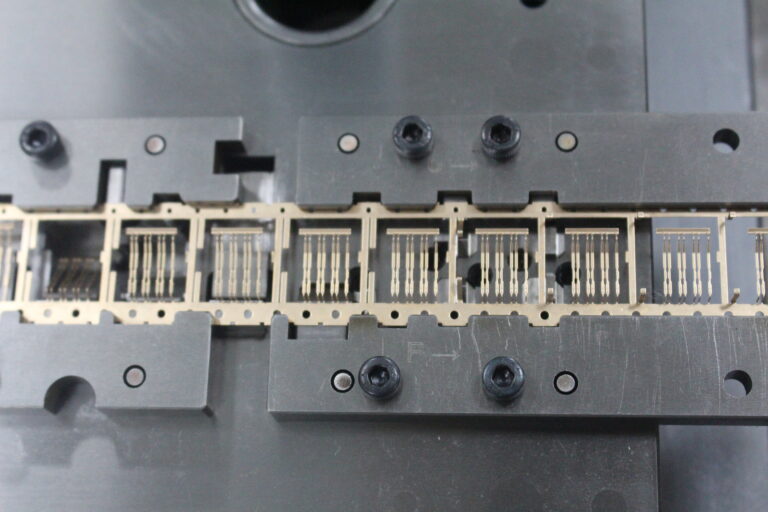

Dies and Tooling – The Heart of the Operation

Dies are essentially metal molds, tailored to cut or form the sheet metal into the desired shape. They’re custom-built and incredibly precise, usually made from hardened steel. Depending on the complexity of the part, you might use:

- Progressive dies – great for high-volume runs with multiple steps

- Compound dies – perform punching and forming in one go

- Forming dies – used when bending and shaping is needed

Each type serves a distinct purpose and is selected based on production needs.

Choosing the Right Materials

Not every metal behaves the same under pressure. That’s why selecting the right material is a crucial step. Common materials include:

- Stainless steel (strong and corrosion-resistant)

- Aluminum (lightweight and flexible)

- Copper alloys and brass (good electrical conductors)

Each metal has its own properties—like ductility and hardness—that impact how it responds during stamping.

Press Machines – The Workhorses

This is where the actual stamping dies happens. Press machines apply the necessary force to shape the metal using the die. Two of the most commonly used are:

- Mechanical presses – fast, efficient, and great for most jobs

- Hydraulic presses – slower but better for deep or complex forms

And let’s not forget the importance of metal stamping supplies like high-precision cutting tools and alignment systems, which keep everything running smoothly and consistently

Types of Metal Stamping dies Techniques

Just like you wouldn’t use the same tool to fix a car and build a bookshelf, metal stamping comes in different techniques depending on what you’re trying to create.

प्रगतिशील डाई स्टैम्पिंग

This is a go-to for high-volume runs. A strip of metal moves through multiple stations, with each station performing a specific task. By the time it reaches the end, the part is fully formed and ready.

ट्रांसफर डाई स्टैम्पिंग

Instead of the strip moving through stations, individual parts are mechanically transferred between them. Ideal for larger or more intricate components where orientation matters.

Four-Slide (or Multi-Slide) Stamping

This method uses four tools simultaneously, which is perfect for complex parts that need bends from different directions.

Fine Blanking

Used when you need ultra-clean cuts and smooth edges. Common in gears, electronics, and precision instruments.

Deep Drawing

Great for hollow or cylindrical parts like cans, sinks, or battery casings. It stretches the metal without cracking or weakening it.

Each method has its niche. The choice depends on the size, shape, and volume of the part being produced.

Why Precision Metal Stamping dies Is a Game-Changer

So, what makes all of this worth it?

- High-Speed Output

With everything set up correctly, precision stamping can churn out parts faster than most other methods.

- Accuracy You Can Count On

You get the same result every time, even when you’re producing thousands of units. That kind of consistency is hard to match.

- Long-Term Cost Savings

Sure, the upfront tooling might seem steep—but the long-term savings in labor, waste, and rework are undeniable.

- Flexibility for Creative Design

Have a tricky part with odd shapes or multiple bends? Stamping can handle it.

- Seamless Integration with Other Processes

Need additional finishing touches? Combine stamping with CNC work to achieve even higher versatility.

The Step-by-Step Manufacturing Workflow

Now that you know the techniques, let’s talk about how everything fits together in a typical precision stamping project.

- Design and Prototyping

Engineers create CAD models and simulate how the part will react under stress. This is where ideas meet feasibility.

Die and Tool Fabrication

Once the design is approved, the dies are made. This is often the most time-consuming and expensive step—but it sets the tone for everything that follows.

- Machine Setup

Machines are calibrated, materials loaded, and safety checks performed. Everything needs to be dialed in perfectly. - Production Run

Sheets of metal are fed through the press. Depending on the job, this could be hundreds—or hundreds of thousands—of parts per day. - Inspection and Quality Control

Using tools like micrometers and laser scanners, every part is checked for consistency. Some facilities even use real-time inspection systems.

Bonus tip: CNC machining is often used post-stamping for drilling holes or refining edges—bridging the gap between bulk production and fine-tuned craftsmanship.

At last

By now, you’ve probably gained a new appreciation for how essential—and complex—precision metal stamping really is. It’s more than just pressing metal into shape. It’s a process built on careful planning, smart engineering, and the seamless use of modern tools and machines.

Whether you’re in aerospace, electronics, or automotive, knowing how precision stamping works can help you make better decisions—from sourcing the right metal stamping supplies to choosing materials that fit your performance goals.

And here’s the exciting part: with advancements in CNC machining, robotics, and automation, this field continues to grow, opening doors for innovation that were impossible a decade ago.

So the next time you hold a finely crafted metal part, you’ll know there’s a world of engineering, design, and manufacturing mastery behind it.

Ready to see what precision metal stamping can do for your next big idea?

Check out our manufacturing services

We offer efficient, high-quality manufacturing solutions tailored to your needs, from prototyping to full-scale production, ensuring precision and quick turnaround times.

Check out our SAMPLE PRODUCTS

Discover our quality sample products that highlight our innovation and manufacturing excellence.

coming soon

Lorem ipsum dolor sit amet,

coming soon

Lorem ipsum dolor sit amet,