How to Choose a Precision Manufacturing partner

SSP "Tanınmış zımba kalıp üretim servis sağlayıcısı – On yıllardır sektördeyiz."

Let’s learn about from the very best in the industry.

6 Key Factors for Selecting a Precision Manufacturing Partner

Selecting the right precision manufacturing partner is crucial when your project demands parts with tight tolerances and exacting standards. The right partner ensures each component meets your design specifications, stays on schedule, and maintains consistent quality. This decision can make or break your project, so it’s important to choose wisely.

In this guide, we’ll explore key factors for choosing a precision manufacturing partner, from defining your project requirements to evaluating technical capabilities, quality control, experience, communication, and capacity. Whether you’re based in the US, Mexico, or the EU—or even working with a precision manufacturer in China—these insights will help you find a partner who supports your goals and helps your project succeed.

Understand Your Project Requirements for Precision manufacturing

Before evaluating any supplier, clarify what your project actually needs. Start by defining part specifications clearly: what materials, dimensions, tolerances, and finishes are required? Are there special processes (heat treatment, plating, coatings) or certifications needed? Consider any industry regulations or standards that apply (for example, aerospace parts often need AS9100 certification, medical devices may require ISO 13485, and automotive components might require IATF 16949 compliance).

Also determine the expected volume and timeline for your project.

-

- Specifications: Outline the materials (aluminum, steel, titanium, plastics, etc.), dimensions, tolerance bands (e.g. ±0.001″), and finish quality (polished, anodized, etc.) your parts demand.

- Include any secondary processes like heat treating or plating in your specifications.

- Volume and Scale: Decide if you need a few prototypes, low-volume batches, or high-volume production. A precision manufacturing partner should match your required scale and growth plans.

- Some machine shops specialize in quick-turn prototyping, while others handle large-scale runs efficiently.

- Standards and Compliance: Identify relevant industry standards or certifications.

- For instance, aerospace parts often demand AS9100 certification and traceability, while medical components may require ISO 13485 and FDA documentation.

- Budget and Timeline: Set realistic cost targets and deadlines for your project.

- Clear timelines ensure the partner can meet your schedule, and defining your budget helps find a provider with a suitable pricing model.

- Specifications: Outline the materials (aluminum, steel, titanium, plastics, etc.), dimensions, tolerance bands (e.g. ±0.001″), and finish quality (polished, anodized, etc.) your parts demand.

By nailing down these project requirements up front, you can communicate clearly with potential partners. They can then tell you exactly how they’ll meet your needs, which avoids surprises later on.

Evaluate Technical Capabilities for precision manufacturing

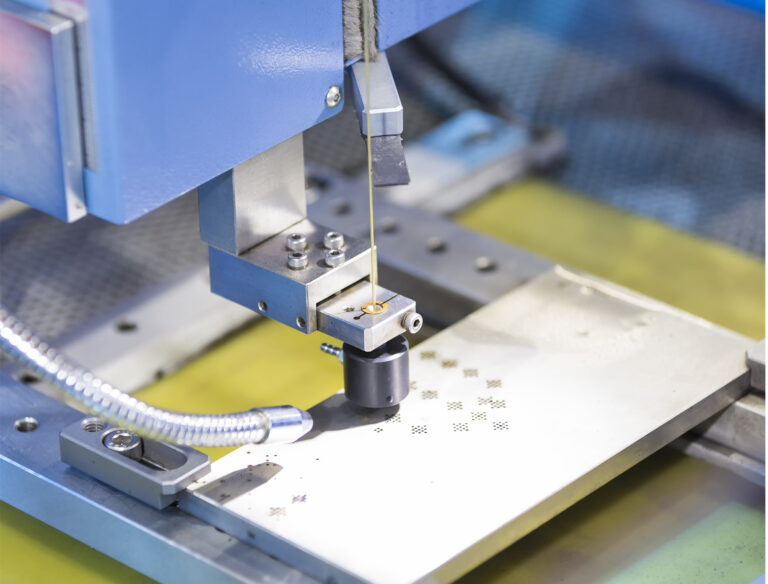

Next, look closely at the supplier’s machinery, processes, and technology. A top-tier precision manufacturing partner will invest in modern equipment and continuous training.

- What CNC machines do they use (multi-axis mills, Swiss turning, CNC lathes, etc.)?

- Do they have advanced capabilities like 5-axis machining, micro-machining, or electrical discharge machining (EDM)?

- Are they equipped to handle your materials (metals, plastics, composites) and special processes?

To break it down, consider:

-

- Advanced CNC Equipment: Ensure the shop has the right machines for your project. Multi-axis CNC mills, Swiss-style lathes, and synchronized pallet systems can handle complex geometries and tight tolerances.

- Ask if they regularly update their machines and controllers to the latest technology.

- Software and Automation: Check that the partner uses sophisticated CAD/CAM software and automated processes. Modern shops often employ computer simulation, toolpath optimization, and even robotics or lights-out machining to improve consistency and repeatability.

- Material and Process Range: Verify that they work with the materials you need (e.g., stainless steel, aluminum, titanium, engineered plastics) and offer required processes (finishing, heat treatment, plating).

- A precision manufacturer in China, for instance, might offer extensive material capabilities at a competitive cost, but also consider how that fits your quality standards and logistics.

- Digital Capabilities: Look for partners embracing smart manufacturing practices—like IoT-enabled machine monitoring, digital work instructions, or automated inspection systems. These technologies can boost quality and speed.

- Advanced CNC Equipment: Ensure the shop has the right machines for your project. Multi-axis CNC mills, Swiss-style lathes, and synchronized pallet systems can handle complex geometries and tight tolerances.

As you evaluate technical capabilities, keep in mind both your immediate requirements and possible future needs. The right partner should have enough flexibility in tools and technology to adapt if your design changes or if you scale volume.

Review Quality Control Processes for precision manufacturing

Quality can’t be an afterthought. Your precision manufacturing partner should have a robust quality management system in place. Look for these key elements:

-

- Certifications: Check for industry-standard quality certifications.

- ISO 9001 certification is a minimum expectation; aerospace firms should also consider AS9100, medical device customers may look for ISO 13485, and automotive projects often require IATF 16949. These certifications show a commitment to consistent processes.

- Inspection Equipment: Verify that the facility uses precise measurement tools.

- Coordinate Measuring Machines (CMM), vision systems, laser scanners, and calibrated gauges should be part of their arsenal. Regular calibration of instruments is crucial.

- Process Controls: Ask how they control each step of production.

- Do they use Statistical Process Control (SPC) or in-process checks? A partner should document every step, from initial setup to final inspection, reducing the risk of defects slipping through.

- Traceability and Documentation: Ensure they maintain full traceability of materials and processes.

- Detailed record-keeping, including material certificates and inspection reports, is vital. This is especially important for regulated industries, where you may need to provide proof of quality for audits or certifications.

- Certifications: Check for industry-standard quality certifications.

By reviewing these quality control processes, you can be confident that your parts will meet specifications consistently and any issues are caught early. Strong quality assurance means less rework and more reliability for you.

Analyze Experience and Industry Expertise for your Precision manufactuirng

Industry knowledge is a major advantage. A supplier familiar with your sector will understand your challenges and standards. Evaluate their experience and expertise:

- Relevant Industry Experience: Check if they have worked with companies in your industry (aerospace, medical, automotive, electronics, etc.).

- Ask for examples of similar projects or parts they have produced. A partner who has made parts for your field will be faster at understanding your requirements and potential pitfalls.

- Reputation and Track Record: Research the company’s history and stability.

- How long have they been in business? Look for client testimonials, case studies, or reviews. A long-standing precision manufacturer with repeat customers is a good sign of reliability.

- Team Qualifications: Consider the skill level of their staff.

- A highly trained engineering and machining team (CNC programmers, toolmakers, quality inspectors) indicates expertise. You may ask about certifications of key personnel or training programs the company provides.

- Innovation and Problem-Solving: Notice if the partner has experience solving tough manufacturing problems or innovating with designs.

- Engineers who offer design-for-manufacturing feedback or creative solutions can save you time and money. Suppliers who invest in continuous improvement (lean manufacturing, Six Sigma) often deliver better results.

- Relevant Industry Experience: Check if they have worked with companies in your industry (aerospace, medical, automotive, electronics, etc.).

By analyzing their background, you’ll gain confidence that the partner can meet the demands of your project. An experienced team is more likely to foresee issues and deliver parts that work right the first time.

Assess Communication and Collaboration

A manufacturing precision isn’t just a vendor—they’re part of your extended team. Strong communication and collaboration skills are essential:

-

- Responsiveness: Notice how quickly they respond to your initial inquiries and RFQs.

- A partner who answers questions clearly and promptly demonstrates that they’ll be attentive throughout the project. Pay attention to whether they understand your needs from the start.

- Project Updates: Ensure they provide regular updates and are transparent about the process.

- Good partners will schedule check-ins or use project management tools to keep you in the loop. You should feel comfortable contacting them with questions at any time.

- Collaboration and Feedback: The best machinists collaborate on design improvements.

- Ask if the team can suggest cost-saving or performance-enhancing changes. A partner who actively discusses manufacturability with your engineers adds value.

- Cultural and Regional Considerations: If your partner is overseas, be mindful of language and time-zone differences.

- For example, partnering with a precision manufacturer in China or Mexico may offer cost or logistical benefits, but plan for clear communication channels, translated documentation if needed, and a contact person who can bridge any gap.

- Responsiveness: Notice how quickly they respond to your initial inquiries and RFQs.

A reliable partner communicates openly and works with you to solve problems together, rather than just issuing a price quote and collecting payments. Good collaboration builds trust and keeps the project on track.

Consider Capacity, Scalability, and Turnaround Time

Finally, assess whether the partner can deliver what you need when you need it. Key points to examine include:

- Production Capacity:Understand the shop’s workload and flexibility.

- Do they operate multiple shifts? Can they handle peak demand? A large precision manufacturing facility or a precision manufacturer in China may offer high capacity and quick scalability, but confirm they have the manpower and machines in place to avoid bottlenecks.

- Scalability: Consider your future needs.

- If you plan to grow or move from prototyping to production, the partner should be able to scale with you. Ask if they can expand production (e.g. add machines or shifts) or partner with sister facilities for larger orders.

- Turnaround and Lead Time: Ask for typical lead times for similar jobs.

- Quick turnaround is often crucial in industries like automotive or medical. Ensure the partner’s quoted schedule aligns with your timeline, and whether expedited options are available if needed.

- Logistics and Location: Factor in shipping and handling.

- If speed is essential, a local shop (US, Mexico, or EU) may be preferable to avoid long transit times. If you’re working globally, note that a precision manufacturer in China might take longer for delivery, so build shipping time into your project schedule.

By carefully evaluating capacity and timing, you’ll choose a partner that can reliably meet your schedule without compromising quality. A good partner will help you plan realistic production schedules and avoid costly delays.

Sonuç

Choosing a precision manufactuirng partner is a strategic decision that impacts the success of your manufacturing project. By carefully defining your requirements and vetting partners on their technical capabilities, quality control, industry experience, communication, and capacity, you’ll find a trusted ally. The right precision manufacturer or machining service will act as an extension of your team—delivering components on time, on budget, and to your exacting specifications. Take the time to apply these criteria, and you’ll select a partner who truly supports your goals, setting the stage for long-term success in any industry.

Check out our manufacturing services

We offer efficient, high-quality manufacturing solutions tailored to your needs, from prototyping to full-scale production, ensuring precision and quick turnaround times.

Check out our SAMPLE PRODUCTS

Discover our quality sample products that highlight our innovation and manufacturing excellence.