INJECTION MOLDING PARTS

- Temel Uzmanlık: Çeşitli uygulamalar için hassas enjeksiyon kalıplama konusunda uzmanlaşmıştır.

- Özel Çözümler: Çeşitli ürün yapıları, malzemeler ve kalınlıklar için özel tasarımlar.

- Etkili İletişim: AutoCAD, Creo ve SolidWorks gibi yazılımlarda ve net müşteri etkileşimleri için birden fazla dilde yetkin.

- Üretim Kontrolü: Şirket içi takım yapımı ve deneme yetenekleri, tasarımdan üretime kadar tam gözetim sağlar.

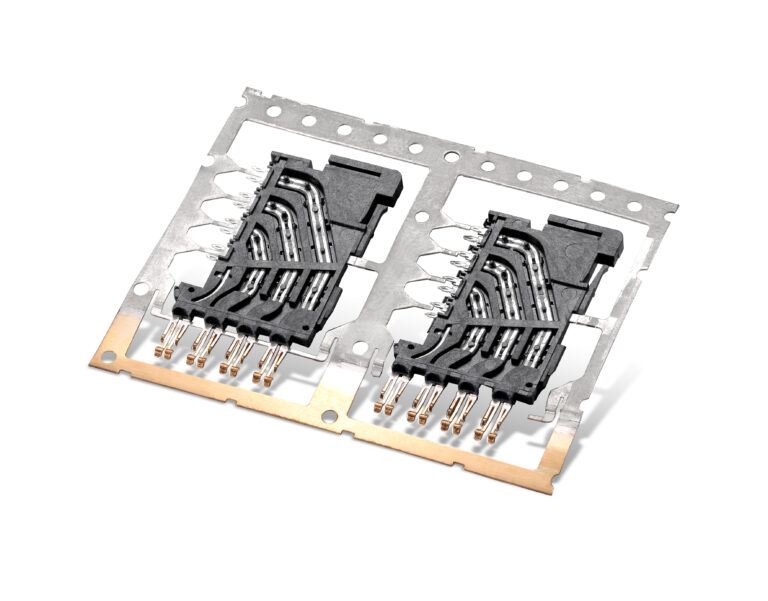

- Kalıplama Teknikleri: Çok yönlü çözümler için saf enjeksiyon kalıplama, insert kalıplama ve üst kalıplama konusunda deneyimlidir.

Üretimimizin Sanatı ve Bilimi....

Üretim sürecimizde yaratıcılık ve hassasiyeti nasıl harmanladığımızı keşfedin. İleri teknoloji ve yetenekli işçilik kullanarak ham maddeleri beklentileri aşan yüksek kaliteli ürünlere dönüştürüyoruz.

Transform Your Projects with Cutting-Edge Injection Molding Solutions

In today’s competitive manufacturing landscape, precision, efficiency, and quality are non-negotiable. At SSP, we specialize in delivering high-performance injection molding solutions that empower businesses to bring their most innovative ideas to life. Whether you’re developing prototypes or scaling up for mass production, our expertise ensures your plastic components meet the highest standards of durability, functionality, and design excellence.

Why Choose Injection Molding?

Injection molding is one of the most versatile and cost-effective manufacturing processes for producing high-volume plastic parts with unmatched consistency and precision. From automotive components and medical devices to consumer electronics and packaging, this method enables complex geometries, tight tolerances, and superior material performance. By leveraging advanced injection molding technologies, we help you:

Reduce production costs with efficient material use and minimized waste.

Accelerate time-to-market with rapid prototyping and scalable manufacturing.

Enhance product quality with uniform, defect-free parts.

Achieve design flexibility for intricate shapes and custom finishes.

Our Capabilities: Precision Engineered for Your Success

At SSP, we combine state-of-the-art machinery, industry-leading expertise, and a customer-centric approach to deliver solutions tailored to your exact requirements.

1. Custom Plastic Injection Molding

No two projects are alike, which is why we offer fully customized molding solutions. Our team works closely with you to:

Select the optimal materials (thermoplastics, elastomers, or engineered resins).

Optimize part design for manufacturability (DFM) to avoid costly revisions.

Implement precision tooling for high-repeatability production.

2. Rapid Prototyping & Low-Volume Production

Need to test a concept before full-scale manufacturing? Our rapid prototyping services allow you to iterate quickly and refine designs without delay. We support:

3D-printed molds for fast turnaround.

Bridge tooling for mid-volume runs.

Overmolding & insert molding for multi-material components.

3. High-Volume Manufacturing

When you’re ready to scale, our facilities are equipped for large-scale production with:

Multi-cavity molds to maximize output.

Automated systems for consistent quality.

Just-in-time (JIT) delivery to streamline your supply chain.

Industries We Serve

Our injection molding expertise spans diverse sectors, including:

Automotive: Durable under-the-hood components, interior trim, and connectors.

Medical: FDA-compliant, sterile-grade parts for devices and equipment.

Consumer Goods: Ergonomically designed housings, packaging, and wearables.

Industrial: High-strength gears, enclosures, and fluid-handling systems.

Transform your projects with our high-quality injection mold solutions! At MW+, we specialize in creating custom plastic components tailored to your exact specifications. Our experienced team leverages state-of-the-art technology to ensure precision and durability in every product we manufacture.

Whether you’re looking for rapid prototyping or large-scale production, we provide flexible solutions to meet your unique needs. Our commitment to excellence means you can trust us to deliver products that enhance your project’s quality and performance.

Partnering with us means you’ll benefit from our expertise in injection molding, allowing you to streamline your manufacturing processes and reduce costs. Let’s collaborate to bring your ideas to life and elevate your product offerings. Choose [Your Company Name] for innovative injection molding solutions that truly make a difference!

INJECTION MOLDING PARTS MANUFACTURING

Injection Mold Products for Custom Solutions