Signs Your Stamping Dies Need Maintenance.

SSP is well known Stamping dies manufacturing services provider. Working in this sector for a decades .

lets learn about from the very best in the industry.

5 Warning Signs Your Stamping Dies Need Maintenance or Replacement

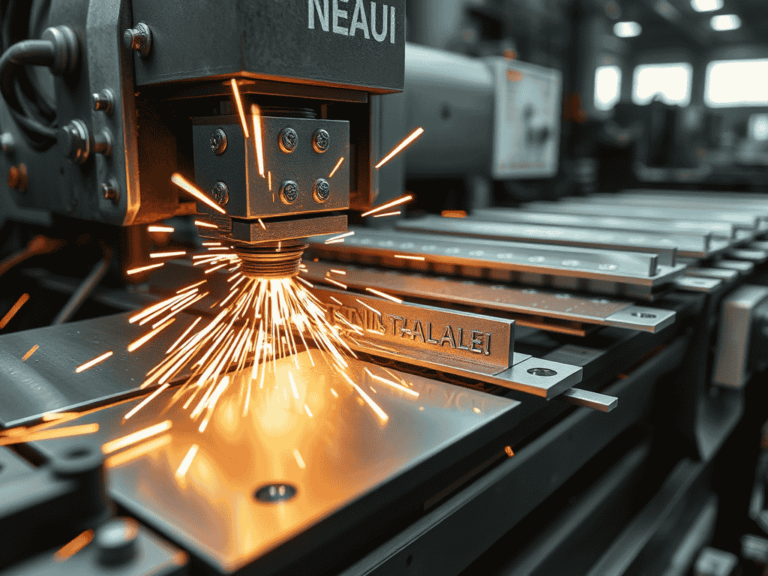

Figure: Technicians inspect stamping dies for wear in a toolroom. Your stamping dies quietly send signals long before a catastrophic failure. As a tool-and-die pro, you know that ignoring subtle clues can lead to big problems. Unplanned downtime isn’t cheap – it includes lost production, idle labor, quality checks and scrap costs By watching for warning signs and acting early, you and your team can avoid hours (or even days) of lost production. Are your dies telling you they need help? Let’s examine five clear warning flags.

Stamping dies Part Quality Issues – Burrs and Out-of-Spec Dimensions

Have you noticed more burrs, nicks or rough edges on stamped parts? These defects are classic red flags. Sharp dies should cut cleanly, so if parts suddenly come off with burrs or inconsistent edges, the tooling is probably dull or misalignedwisconsinmetalparts.com.

Likewise, parts drifting out of tolerance (even slightly) means metal isn’t being cut or formed precisely. Even small surface imperfections force rework or scrap. In fact, worn dies “may produce parts with inaccurate dimensions or surface imperfections, increasing the amount of scrap produced”yuntaimould.com. Keep an eye on critical dimensions; catching burrs or tolerance shifts early (for example on a stamped terminal strip or copper busbar part) lets you fix the die or resharpen edges before quality suffers.

- Burrs or sharp “ears” on edges of stamped pieces.

- Parts measuring even slightly out of spec or rough finish.

- An unexpected jump in scrap or rework volume.

By regularly checking your first and last parts, you’ll see trends. If problems keep appearing, it’s time to sharpen or replace tool steelwisconsinmetalparts.com. Often, the cure for these defects is simple: a quick trip to the toolroom for grinding. Waiting too long, however, means bigger problems later on.

1. Increased Press Load or Unusual Noises on Stamping dies

Does the press feel like it’s working harder than usual? When a die wears or misaligns, your press will demand higher tonnage to form the part. Watch the press ammeter or tonnage readout – a rising trend, even if small, often means greater friction inside the tool. You may also hear it: squeaks, clanks or grinding sounds are a wake-up call. These noises usually come from metal-on-metal contact (for example, a stripped bushing or a slightly warped punch), and they won’t stop on their own.

Routine monitoring can catch these early. Advanced shops use vibration or temperature sensors for predictive maintenance – sudden spikes can “provide early warning signs of excessive wear or impending failure”kenenghardware.com. In plain terms, if you start feeling extra vibration through the press or notice the die gets hotter, inspect it immediately. Check die alignment and lubrication – sometimes a worn guide pin or dried grease is the culprit. But don’t ignore noises or “hot spots”; they only worsen tool life and drive up energy costs.

- Press tonnage climbing above normal levels.

- Strange sounds (squeals, chirps, grinding) during the stamping cycle.

- New or unexpected heat buildup on the die.

These are clues that metal parts aren’t sliding and cutting smoothly. Addressing them often means re-aligning the die, re-lubricating, or replacing worn bushings/pins. Left unchecked, a noisy or overloaded press can damage the die (and even the press itself).

2. Rising Scrap Rates, Jams and Downtime

If your line is suddenly producing more scrap or requiring frequent stops, your dies could be the cause. When dies wear, they may misfeed material or leave slugs that jam the press. You’ll see more stamped parts failing inspection, or scrap piling up at the unload station. Even seemingly unrelated issues (like coil feeding problems) can trace back to die wear – for example, springs may weaken and not strip parts cleanly.

✦ Symptom checklist: higher scrap percentage; parts piling up; frequent alarms or die-line stops; clogged scrap chutes.

Stoppages and scrap cost real money. Remember: the downtime, idle operators and retooling efforts often cost far more than routine maintenancemetalformingmagazine.com. If your team is scrambling to clear jams or manually deburr parts every shift, don’t delay – schedule a die inspection. Often a worn punch or an out-of-square die member is the hidden culprit. Fixing it can instantly reduce scrap and keep production flowing.

3. Visible Die Damage – Cracks, Dents and Wear on Stamping dies

Sometimes the warning is right in front of you. When dies get older, you may spot cracks, chipped tooling or deformed surfaces. Regular visual inspections are critical. Open up the die and shine a light inside: look for any cracks in the steel, chips out of punches, or unusual deformation. Also check guide pillars and bushings – excessive clearance or scoring there means the die plates have shifted.

“Detect early signs of wear, such as cracks, misalignments, or surface damage” during inspectionsyuntaimould.com. A small crack in a die component can propagate quickly, leading to catastrophic failure. Likewise, a dent or gouge on a die corner may cause premature wear on that section. Even the stripper plates or pilot pins should be free of deep scratches. Use magnification if needed – sometimes hairline cracks are barely visible.

- Surface cracks or spalls on punches, dies, or guides.

- Deformed or bent die walls, or an uneven gap when the die is closed.

- Loose bolts, broken springs, or any parts moving more than they should.

As one maintenance manual notes, inspect “punches, dies, guide pins, and springs for wear patterns, cracks, or deformation” every runkenenghardware.com. If you find damage, stop and repair. Welding in material, swapping in spare components, or fully regrinding the die face can often restore functionality. Don’t wait for a tiny chip to turn into a major repair job.

5. Worn Components – Springs, Strippers and Guides

Finally, pay attention to the stamping dies internal hardware. Springs, lifter pins, strippers and alignment pins wear faster than the steel plates. Weak or broken springs (for example, on an ejection assembly) will cause inconsistent part ejection.

Worn guide posts make each press stroke misalign a little more, which quickly degrades cut quality. If lifter pins start sagging or ejectors stick, parts can collapse or scuff.

Checklist for components:

- Springs that no longer push parts firmly out of the die.

- Guide and pilot pins with excess clearance or scoring.

- Stripper plates or lifters that stick or drag, indicating low lubrication.

Also watch lubrication points: debris in lube holes or dried grease is a sign you’re overdue for service. As another expert advises, keep dies clean and lubricated – metal shavings and dirt can “impair precision and cause premature wear” if left on the toolkenenghardware.com. Regularly clean out chips and apply fresh lubricant. In short, any component that no longer looks new or operates smoothly should be refurbished or replaced.

结论

Your stamping dies are the heartbeat of your production. By heeding these warning signs – from burrs on parts and higher press loads, to visible cracks and worn springs – you can save big headaches later. Don’t wait for a catastrophic break to act. Instead, schedule regular die checks and preventive maintenance. Sharpening tools, replacing fatigued springs, or swapping in a refurbished die can preserve part quality and prevent unplanned downtime.

You work too hard to let avoidable problems shut you down. When you see those burrs piling up, hear odd noises, or spot damage, take action. Call in your toolmakers or maintenance team, and fix the issue before it gets worse. In the end, attentive die care protects product quality, keeps customers happy, and maximizes your uptime – all of which keeps your bottom line healthy.

Check out our manufacturing services

We offer efficient, high-quality manufacturing solutions tailored to your needs, from prototyping to full-scale production, ensuring precision and quick turnaround times.

Check out our SAMPLE PRODUCTS

Discover our quality sample products that highlight our innovation and manufacturing excellence.