रोबोटिक्स स्पेयर पार्ट्स

High-Wear Parts. Higher Standards. Keep Your Robots Running at Peak Performance.

Engineered for Robotic Reliability – Minimize Downtime, Maximize Uptime.

5/5

Years of experience

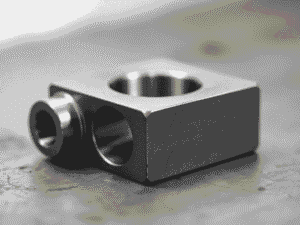

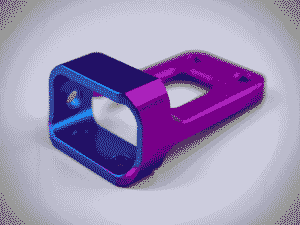

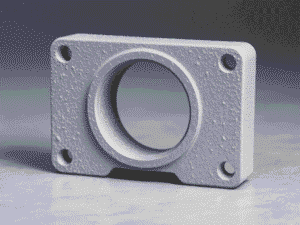

Industrial Robotics Spare Parts - Precision Components

Industrial robotics spare parts are specialized components designed to maintain and restore the functionality of automated systems. Unlike generic replacements, these precision parts are manufactured to meet or exceed OEM specifications, ensuring seamless integration and reliable operation in demanding production environments.

Key Features & Benefits:

High-Performance Servo Systems: Precision motors and reducers with reinforced bearings for consistent torque and positioning accuracy

Durable End Effectors: Ruggedized grippers and tool changers engineered for millions of operational cycles

Precision Motion Components: Linear guides and ball screws with micron-level tolerances for repeatable movement

Engineered for Industrial Applications:

• Automotive manufacturing – where uptime directly impacts production throughput

• Electronics assembly – requiring contamination-free operation

• Heavy payload handling – demanding robust construction and wear resistance

Quality Assurance: All components undergo rigorous testing, including:

Dimensional verification against OEM blueprints

Dynamic load testing under operational conditions

Material certification for critical applications

20,000+ Precision Parts, 150+ Materials

4.9/5

Tolerance Standard

±0.0005" Precision Guarantee

Since 2015

5/5

सतह खत्म

C8-16 μin Ra Mirror Finish

Since 2015

4.8/5

Maximum Workpiece

40" × 28" × 20" Capacity

Since 2015

4.5/5

Material Hardness

Up to 65 HRC Processed

Since 2015

Tolerance for Robotics Spare Parts Services

Limits for nominal size

Metals (ISO 2768- f)

Plastics (ISO 2768- m)

0.5mm* to 3mm

±0.05mm

±0.1mm

Over 3mm to 6mm

±0.05mm

±0.1mm

Over 6mm to 30mm

±0.1mm

±0.2mm

Over 30mm to 120mm

±0.15mm

±0.3mm

Over 120mm to 400mm

±0.2mm

±0.5mm

Over 400mm to 1000mm

±0.4mm

±0.8mm

Over 1000mm to 2000mm

±0.5mm

±1.2mm

Robotics Spare Parts Performance Specifications

| वर्ग | Parameter | Standard Grade | Precision/High-Performance Grade | Validation Method |

|---|---|---|---|---|

| Mechanical Properties | Tensile Strength | 500-700 MPa | 700-900 MPa (Aerospace Alloys) | ASTM E8/E8M |

| Fatigue Life (Cycles) | 1×10⁶ @ 50% load | 5×10⁶ @ 75% load | ISO 12106 | |

| Hardness (Rockwell C) | 32-38 HRC | 40-45 HRC (Case-Hardened) | ASTM E18 | |

| Motion Accuracy | Positioning Repeatability | ±0.05 mm | ±0.01 mm (Laser-Calibrated) | ISO 9283 |

| Backlash | ≤0.1° | ≤0.03° (Preloaded) | DIN 69051 | |

| Durability | Service Life (Hours) | 20,000 | 50,000 (Lubricated) | ISO 3408 |

| Wear Rate (μm/1,000 km) | 15-20 | <5 (DLC-Coated) | ASTM G99 | |

| Thermal Performance | Operating Temperature | -20°C to +120°C | -40°C to +150°C | IEC 60068-2 |

| Thermal Expansion Coefficient | 11.5 μm/m°C | 8.2 μm/m°C (Invar Alloys) | ASTM E228 | |

| Electrical Compliance | Insulation Resistance | 10⁹ Ω | 10¹² Ω (Ceramic-Insulated) | IEC 60664 |

| EMC Susceptibility | 10 V/m | 30 V/m (Shielded) | IEC 61000-4-3 | |

| Material Certifications | RoHS/REACH Compliance | Yes | Yes + Conflict-Free Minerals | ICP-MS Testing |

| Cleanroom Classification | ISO Class 8 | ISO Class 5 (Medical/Electric) | ISO 14644-1 |

| वर्ग | Parameter | Standard Industrial Grade | High-Precision Performance Grade | Validation Method | Industry Benchmark |

|---|---|---|---|---|---|

| Material Properties | Tensile Strength | 500-700 MPa | 700-900 MPa (Maraging Steel) | ASTM E8/E8M | ISO 683-11 |

| Yield Strength | 450-650 MPa | 650-850 MPa | ASTM E8/E8M | DIN 50125 | |

| Impact Toughness | 40 J (Charpy) | 60 J (Charpy @ -40°C) | ASTM E23 | EN 10045-1 | |

| Hardness | 32-38 HRC | 40-45 HRC (Case-Hardened) | ASTM E18 | ISO 6508 |

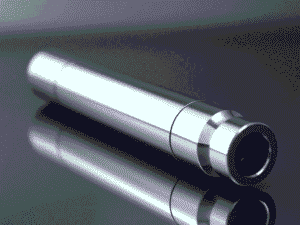

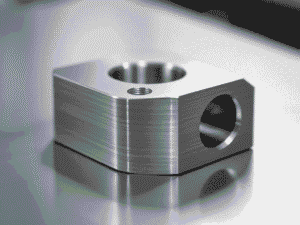

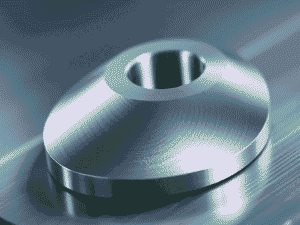

Robotics Spare Parts Surface Finishes

We provide finishes for aesthetics and performance: anodizing, polishing, sandblasting, coatings, and heat treatment. Let’s find the right one!

As Machined

This machined finish is rough and displays tool marks, representing the most basic form of surface treatment without any additional finishing or polishing.

Anodizing

It creates a protective oxide layer on aluminum, increasing corrosion resistance and hardness, and allowing for dyeing to enhance appearance.

Polishing

Polishing smooths surfaces to a high sheen, enhancing appearance and reducing roughness while offering some corrosion protection.

Brushed Finish

A brushed finish has fine, parallel lines for a textured look, enhancing grip and reducing fingerprints.

Sandblasting

Sandblasting uses high-pressure air and abrasive particles to clean or texture surfaces, enhancing adhesion for coatings.

Electropolish

Electropolishing is an electrochemical process that smooths and brightens metal surfaces, removing imperfections and enhancing corrosion resistance.