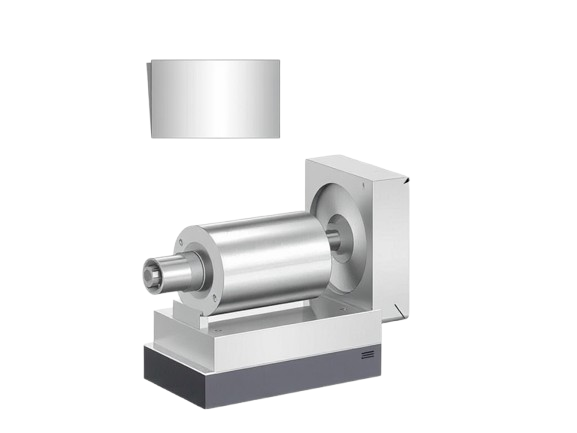

烫印模

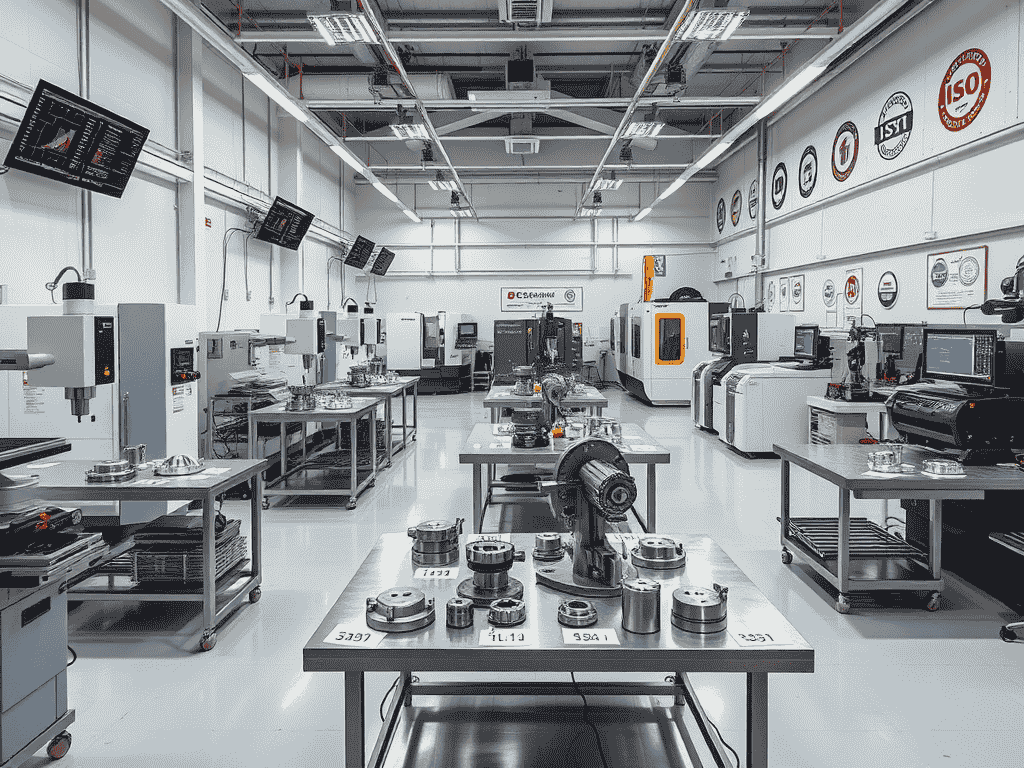

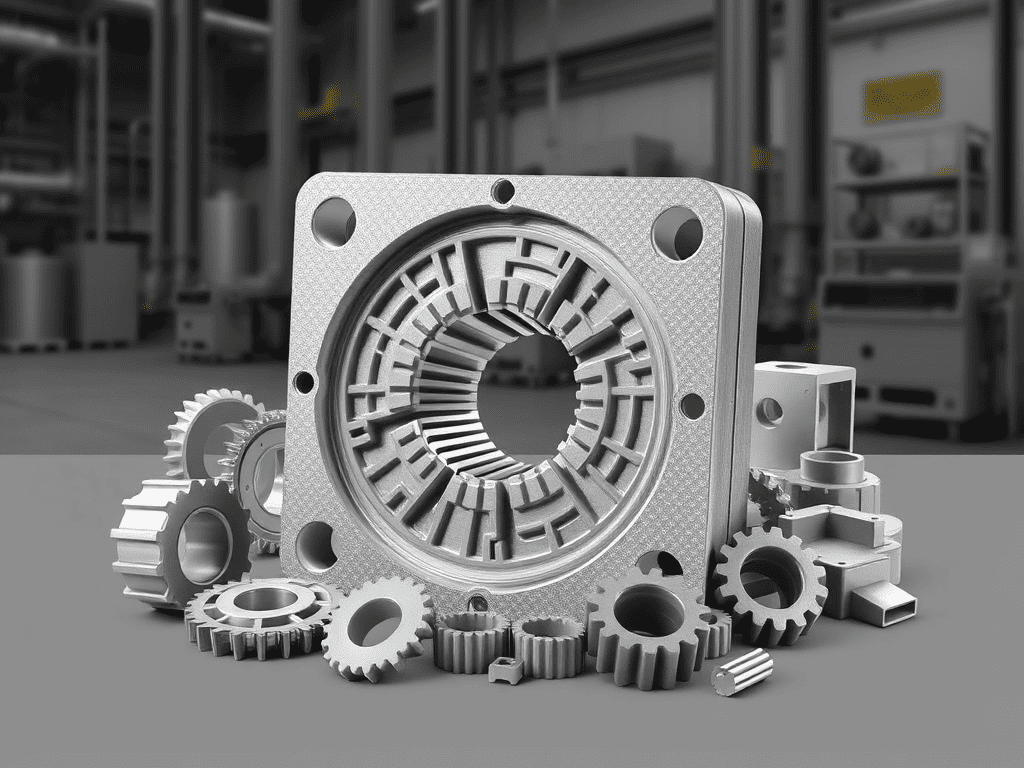

MANUFACTURING

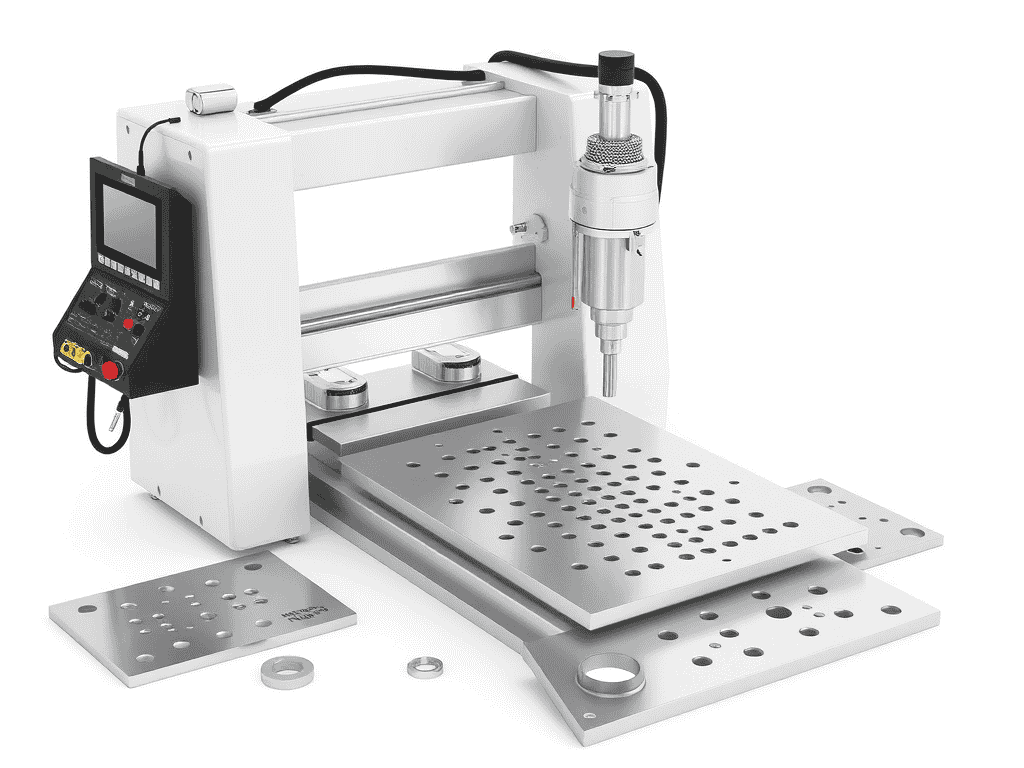

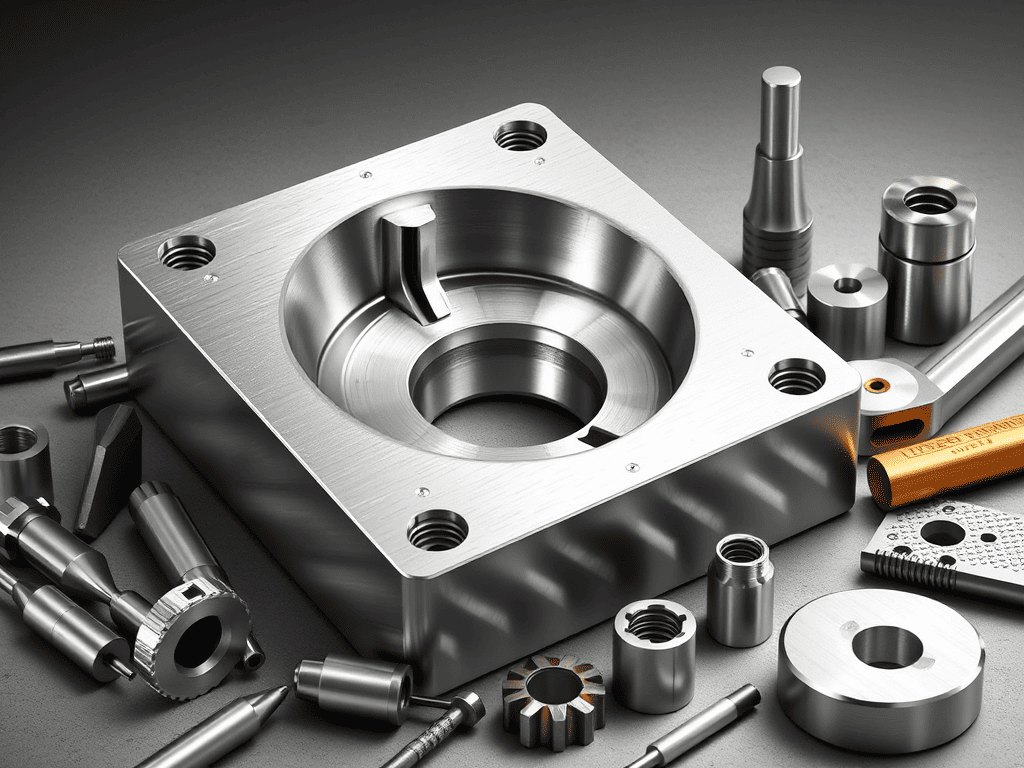

In SSP, We provide custom Stamping dies manufacturing with expert engineering support and DFM analysis. Enjoy fast turnaround times for both low and high-volume production. Transform your vision into reality with exceptional precision and quality.

- Custom Stamping Dies Manufacturing

- 25 多种表面处理,50 多种材料可供选择

- 一站式服务,在线冲压解决方案

- ISO 9001:认证

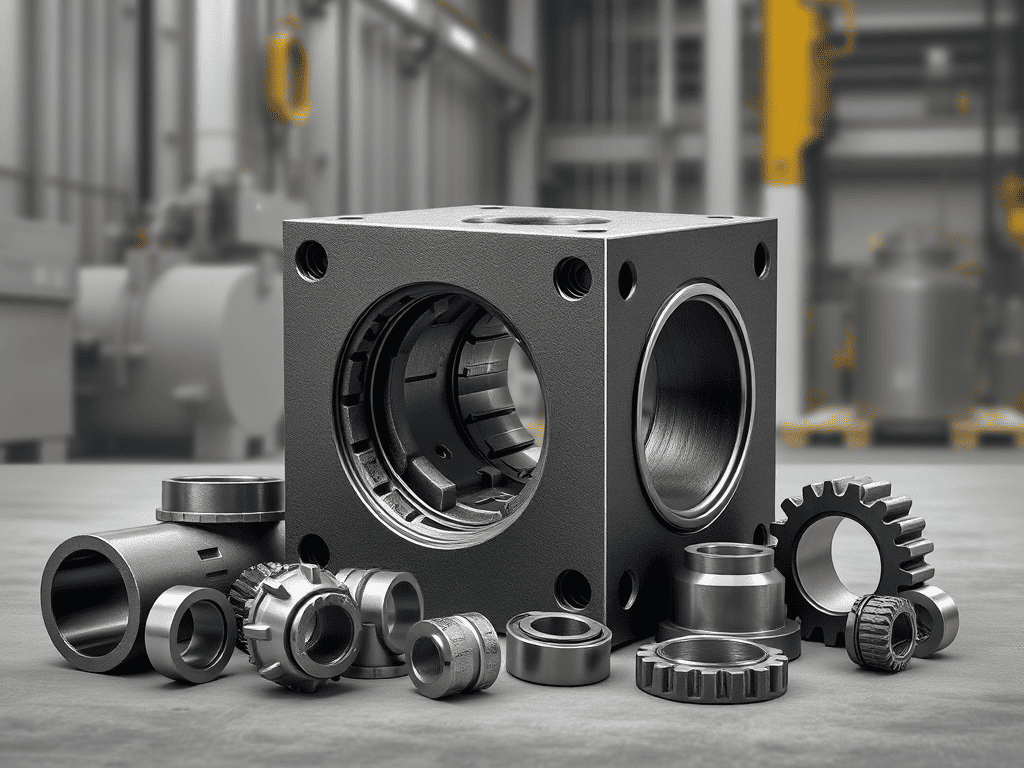

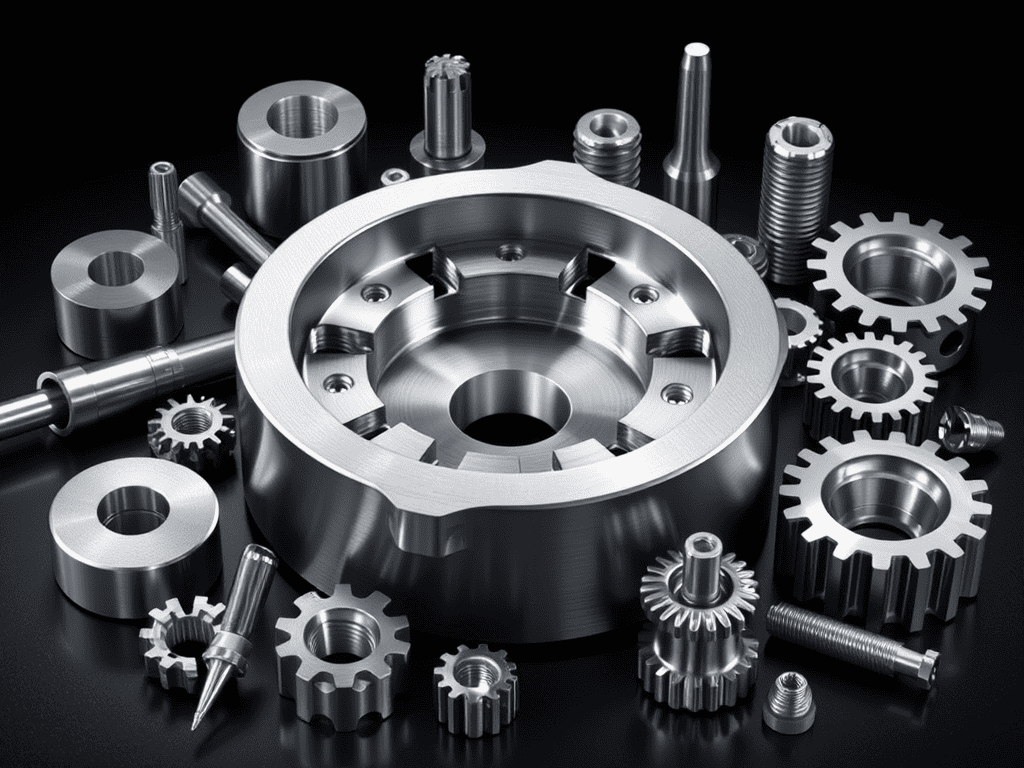

Our Stamping dies manufacturing

We provide professional stamping dies manufacturing services essential for producing accurate, high-quality metal components. Our capabilities include progressive stamping dies, single-stage dies, compound dies, and transfer dies—each suited for different production needs and part complexities.

In addition to die design and fabrication, we offer die maintenance, repair, and modification services to extend tool life and ensure consistent performance. Our precision piercing services use punch-and-die setups to create clean, accurately placed holes in metal parts.

These processes are widely used across automotive, electronics, and appliance industries, enabling efficient production of detailed and functional components. With a focus on precision and reliability, we help businesses streamline their manufacturing and improve overall product quality.

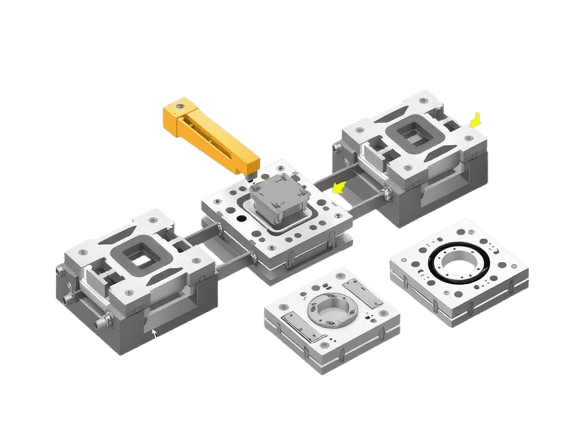

Compound Stamping dies

我们公司提供复合模具冲压服务,一次冲压完成多项操作。这种高效的方法可以对金属零件进行精确的切割和成型,从而缩短复杂设计的生产时间。

消隐

冲裁是冲压模具中的一种高精度金属切削工艺,用于从金属板上加工出平整、边缘干净的零件。冲头和冲模组从材料带中取出完全成型的零件,毛刺最小,尺寸精度最高。

穿孔

Piercing is a precision manufacturing process that creates clean, accurate holes in sheet metal or other materials using specialized dies and high-force stamping piercing. Unlike drilling, piercing produces holes without material loss, making it ideal for high-volume production with tight tolerances.

SSP 的冲压模具制造服务

Progressive Stamping dies manufacturing

As a top die factory, We are industry leaders in providing advanced progressive die stamping solutions, delivering precision-engineered metal components tailored to meet the specific demands of our clients. With a commitment to excellence and innovation, we leverage state-of-the-art technology and extensive expertise to ensure superior quality and efficiency in every project.

我们的综合服务

定制设计与工程: Our team collaborates closely with clients to develop bespoke progressive die stamping designs that align perfectly with their specifications, ensuring optimal performance and functionality.

大批量生产能力:我们拥有最先进的设备,擅长大批量生产,始终保持所有部件的严格公差和卓越质量。

材料多样性和专业知识: We are proficient in working with a wide range of materials, including various grades of steel, aluminum, and copper, allowing us to meet diverse project requirements with precision & progressive die stamping.

快速周转和灵活性:我们的简化流程和自动化系统使我们能够快速交付,迅速适应不断变化的项目需求,同时坚持我们的质量承诺。

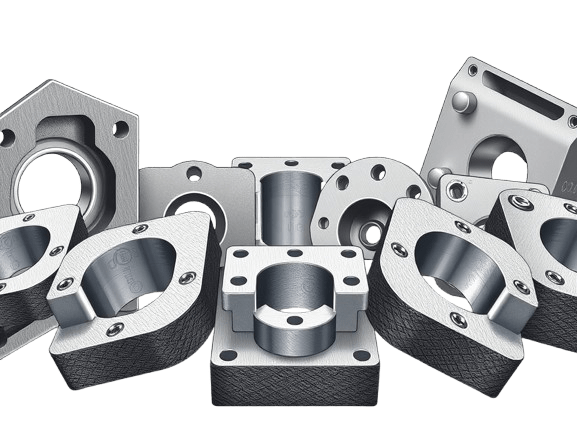

Transfer Stamping dies manufacturing

We specialize in providing sophisticated transfer die stamping solutions in Our Stamping die factory that deliver high-precision metal components for a broad range of industries. With a focus on innovation and quality, we utilize advanced technology and skilled craftsmanship to ensure exceptional results for every project.

我们的综合服务

- Custom Engineering:

We partner with clients to create bespoke transfer die designs that enhance both efficiency and performance, tailored to specific operational needs. - High-Volume Efficiency:

Our advanced transfer stamping machinery allows us to execute rapid production cycles, efficiently handling large orders while upholding stringent quality standards. - Material Mastery:

We offer extensive experience with a variety of materials, including different grades of steel, aluminum, and specialty alloys, ensuring we meet diverse application requirements. - Dynamic Manufacturing:

Our adaptable manufacturing processes enable quick responses to changing project demands, ensuring timely delivery without compromising on quality.

Deep Draw Stamping dies

SSP offers exceptional deep draw services, specializing in transforming flat metal sheets into intricate, high-precision components. With a commitment to quality and innovation, the company serves a diverse range of industries effectively.

我们的综合服务

- 精密工程: Our state-of-the-art deep draw stamping die manufacturing processes create intricate shapes with exceptional accuracy, ensuring consistent quality in every component.

- Flexible Production Capacity: Our facilities are designed to accommodate both low and high-volume die production, allowing us to adapt to the specific needs of each project seamlessly.

- Versatile Material Handling: We work with a wide range of materials, including stainless steel, aluminum, and specialized alloys, ensuring we meet the unique requirements of various applications in die manufacturing.

- Collaborative Design Optimization: We partner with clients to refine die designs and enhance manufacturability, resulting in cost-effective, high-quality stamping dies that meet rigorous industry standards.

These featured services represent just one segment of our complete manufacturing solutions portfolio...

"Beyond Standard Manufacturing: We Bring Your Custom Ideas to Life"

"Consult with Our Experts"

最低订购量(MOQ)

我们优先满足您的需求,最低订货量灵活,非常适合小型或原型需求。

Total Parts Manufactured

该指标显示了生产的零件总数,突出了我们的生产效率。

设计

多样性

6000 多种独特的设计可供选择,确保满足各种偏好。

运输

可用性

我们提供全球送货服务,使全球各地的客户都能买到我们的产品。

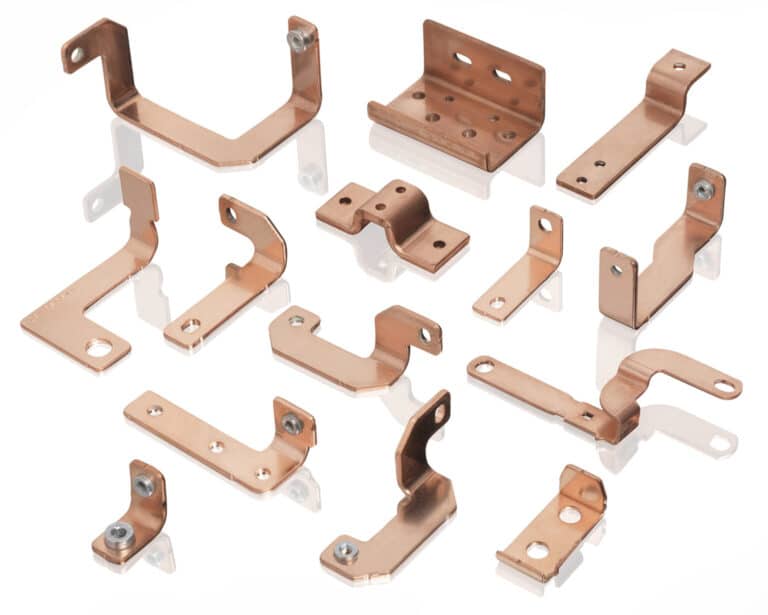

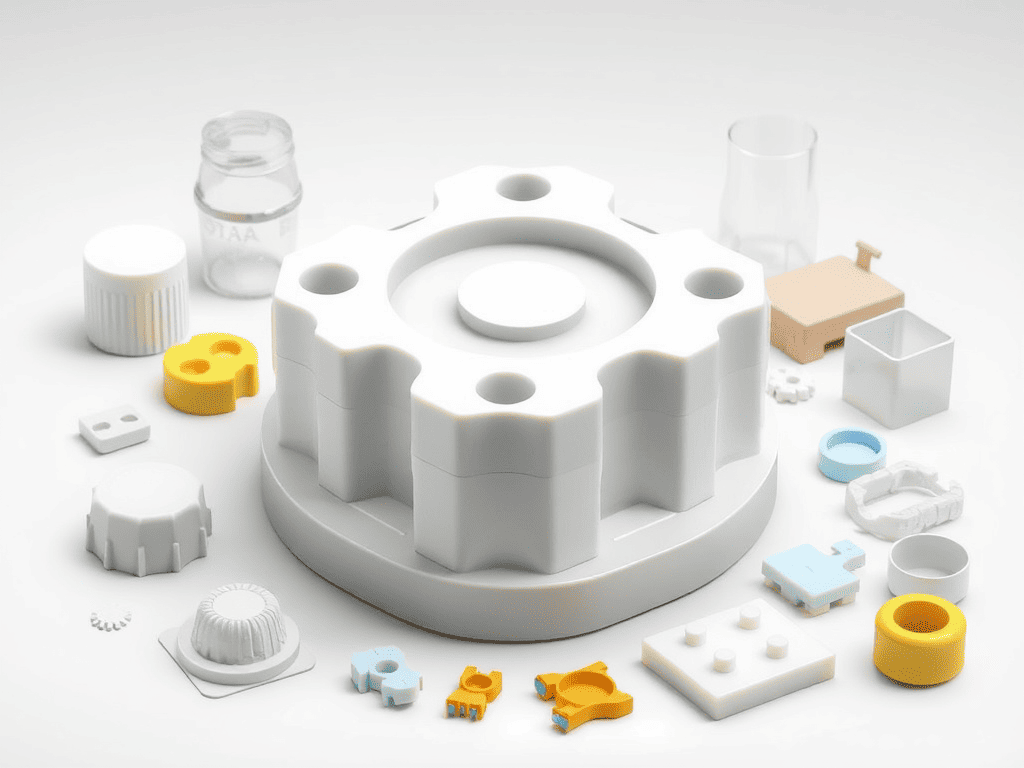

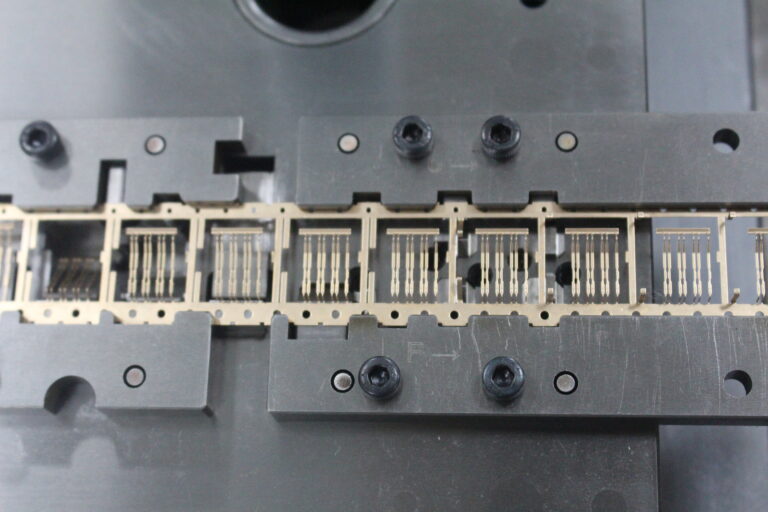

Checkout Our Stamping Dies Products

Discover how we blend creativity and precision in our dies manufacturing process. Using advanced technology and skilled craftsmanship on (busbar, terminal strip, metal stamp kit), we transform raw materials into high-quality products that exceed expectations.

注册(初始信息)

我们仅通过电子邮件发送订单和服务信息,从不共享个人信息或发送垃圾邮件,以确保客户的机密性。

- 电子邮件

- 名称

- 公司名称

填写订单详情

您可以索取不同数量和材料的报价。如果您没有设计文件或完整的项目概念,请通过以下方式联系我们 rockie.liu@ssprecision.com.cn 否则请提交。

- 设计文件

- 材料

- 表面处理

管理订单

提交订单后,您可以在订单管理页面查看订单进度。一般情况下,我们会在 24 小时内更新报价,并通过电子邮件通知您。

- 24 小时报价

- 电子邮件通知

- 进度跟踪

订单确认

确认函应包括订单详细信息,如零件名称或编号、订购数量和要求的交货日期。

- 生产成本

- 付款信息

- 运输信息

How to get an STAMPING DIES MANUFACTURING quote online?

Our stamping dies manufacturing services provide a robust and economical manufacturing solution for producing high volumes of precision metal parts. We facilitate on-demand production, empowering you with unmatched flexibility and efficiency to conquer your manufacturing challenges.

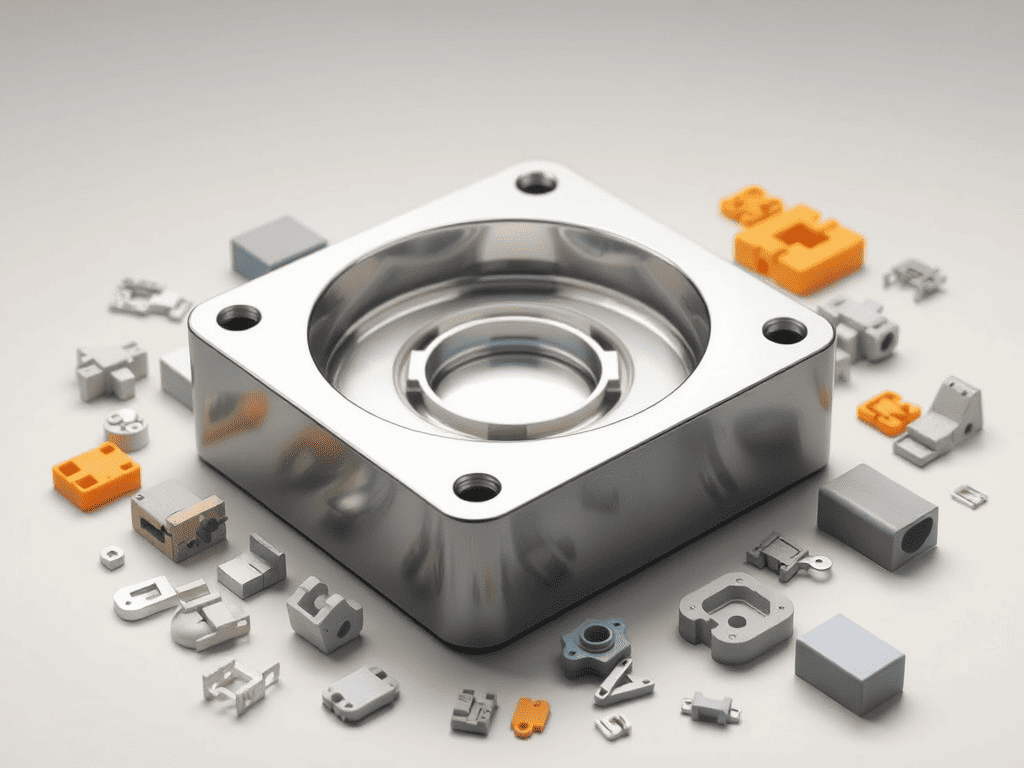

我们的制造工艺

Stamping dies manufacturing services are a highly effective manufacturing process for high-volume production of metal parts. This technique involves shaping metal sheets using a die to create precision components, which are then ejected from the mold after forming. This method ensures efficiency, accuracy, and consistent quality in every finished part.

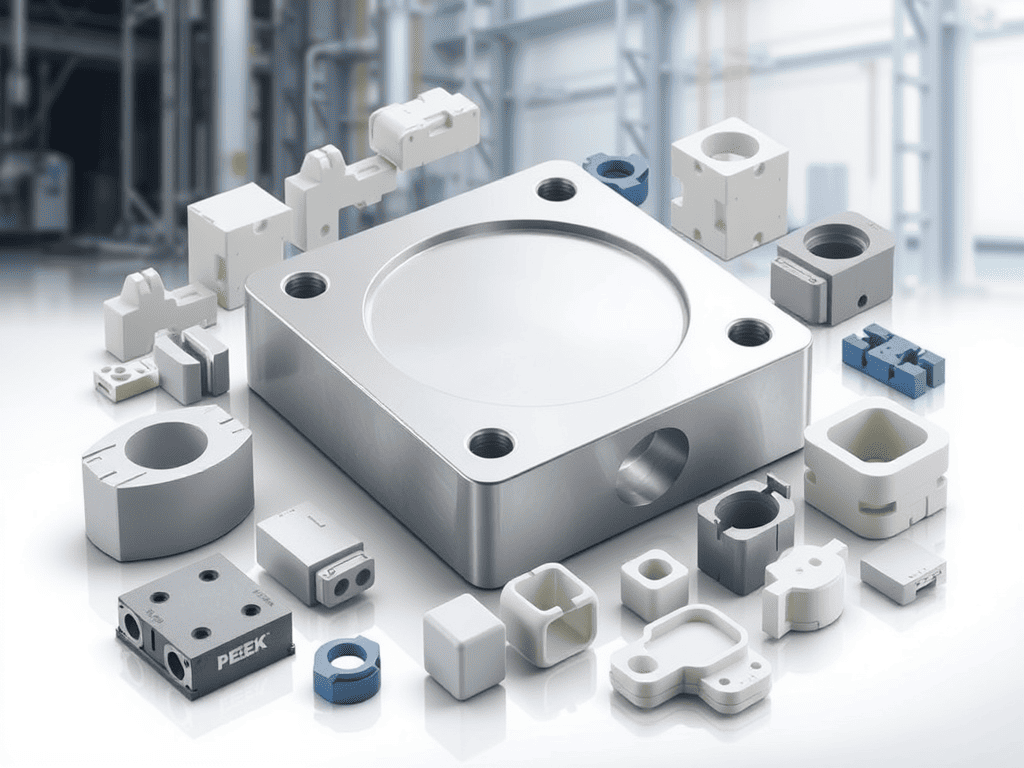

Stamping Die/Piercing Materials ( Materials We Use )

工具钢(高耐磨性)

D3 是一种高碳高铬工具钢,以其出色的耐磨性和保持锋利刃口的能力而著称。它常用于切削工具、模具和要求高耐用性的工业应用。

亚型:

- D3(标准)

- D3 冷作工具钢

预硬工具钢

P21 是一种预硬工具钢,具有良好的机加工性能和耐磨性。由于不需要大量热处理,因此是制造模具和冲模的理想材料。

亚型:

- P21(标准)

- P21+(改进型)

热作工具钢

H11 是一种热作工具钢,以其韧性和抗热疲劳性著称。它可用于高温应用领域,如压铸和锻造。

亚型:

- H11(标准)

- H11A(为提高韧性而改良)

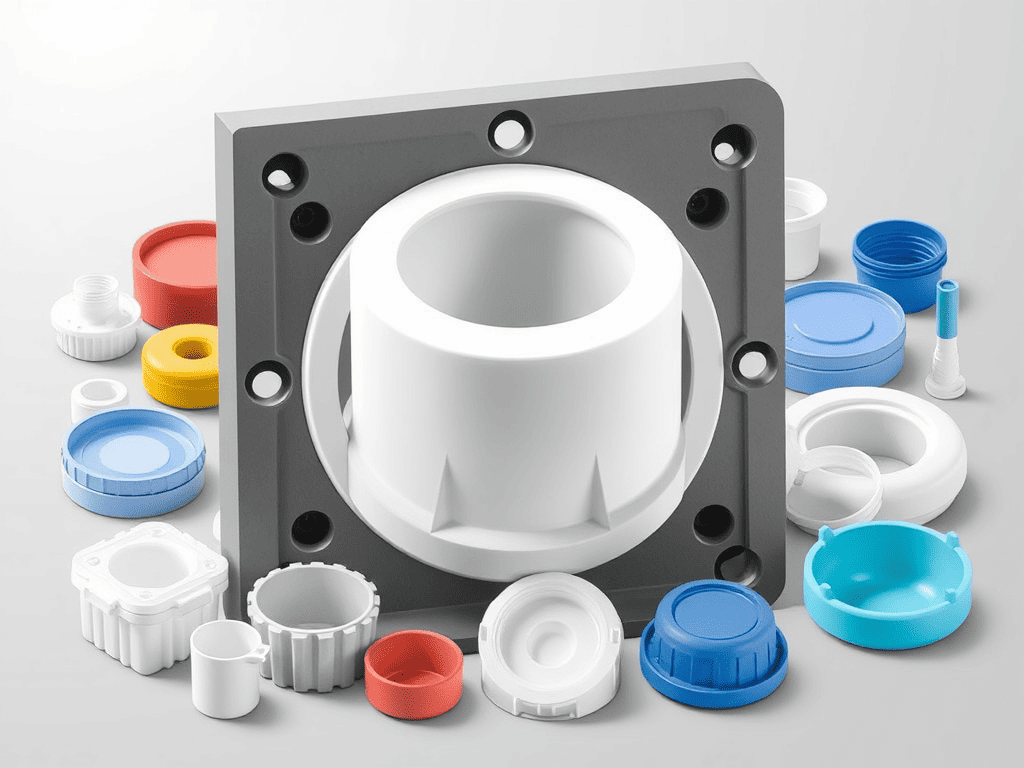

聚甲醛(缩醛)

POM 是一种高性能工程热塑性塑料,以低摩擦、高硬度和出色的尺寸稳定性而著称。它广泛用于精密零件和机械部件。

亚型:

- 聚甲醛-C(共聚物)

- POM-H(均聚物)

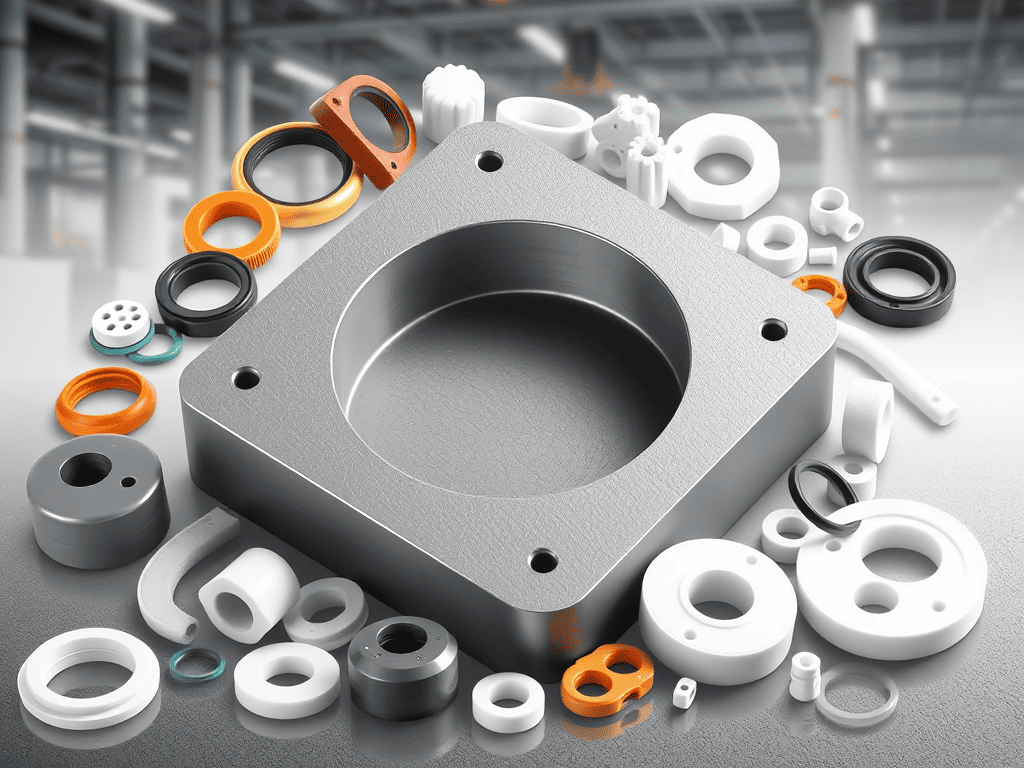

聚酰胺(尼龙)

PA 是一种多功能合成聚合物,以其高强度、韧性、优异的耐化学性和耐磨性而著称,常用于纺织品、汽车部件和工业应用。

亚型:

- 蓝色 PA(尼龙

- PA6(尼龙)+GF15 黑色

- PA6(尼龙)+GF30 黑色

- PA66(尼龙) 米色(自然色)

- PA66(尼龙) 黑色

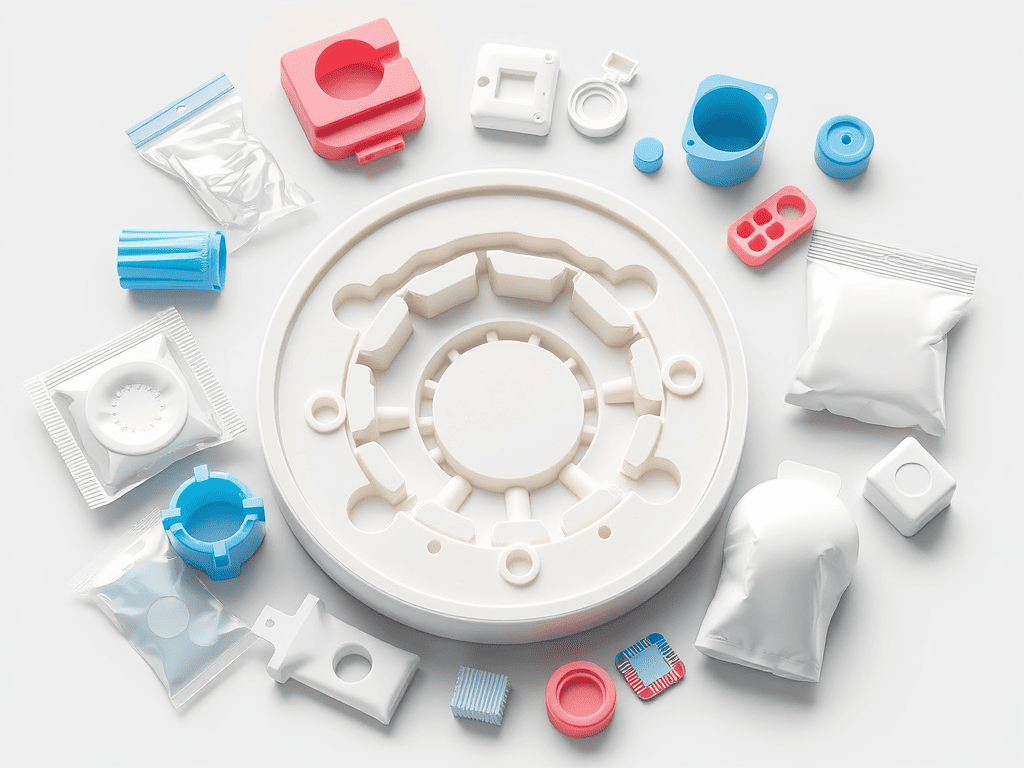

聚丙烯

PP 是一种轻质、耐用的热塑性塑料,以耐化学腐蚀性和多功能性著称。它广泛用于包装、汽车零件和消费品。

亚型:

- PP 均聚物

- PP 共聚物

高密度聚乙烯

高密度聚乙烯是一种强度高、用途广泛的热塑性塑料,以其高强度密度比著称。它常用于容器、管道和塑料瓶。

亚型:

- 高密度聚乙烯(标准)

- 高密度聚乙烯(回收)

低密度聚乙烯

低密度聚乙烯是一种柔韧耐用的热塑性塑料,以低密度和高耐化学腐蚀性著称。它常用于包装薄膜和包装袋。

亚型:

- 低密度聚乙烯(标准)

- 低密度聚乙烯(再生)

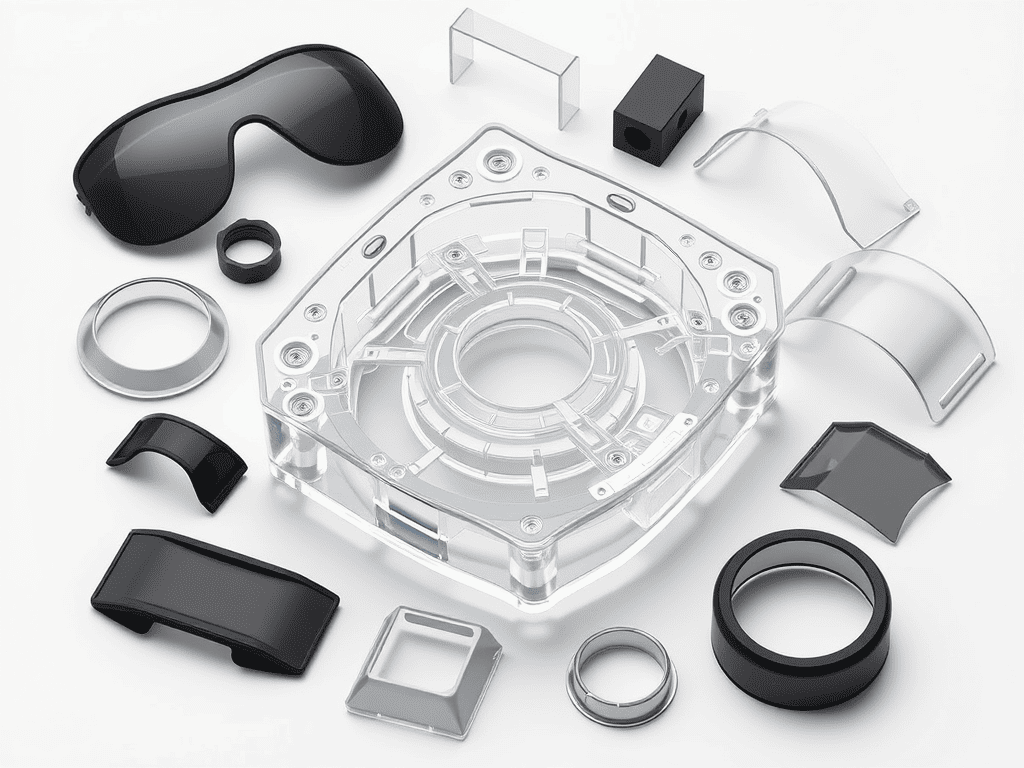

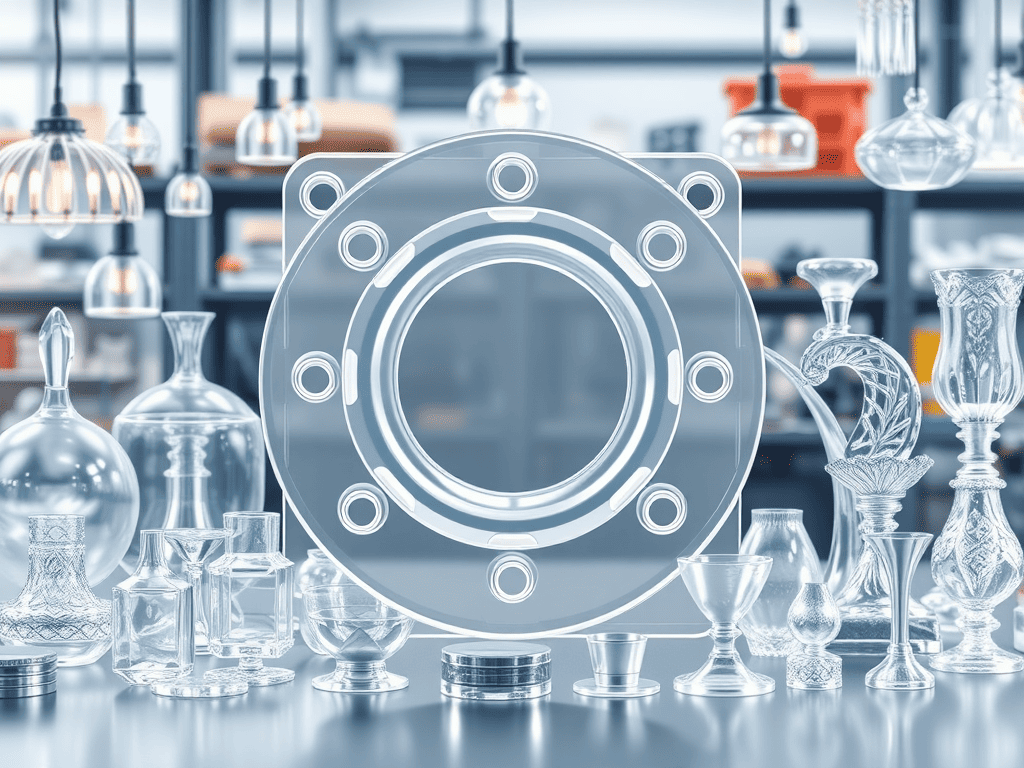

聚碳酸酯

PC 是一种坚固、耐冲击的热塑性塑料,以其清晰度和耐热性著称。它常用于眼镜镜片、安全设备和电子元件。

亚型:

- 个人电脑(标准)

- PC(阻燃)

高抗冲聚苯乙烯

HIPS 是一种坚韧且抗冲击的热塑性塑料,以易于加工和良好的表面光洁度而著称。它常用于消费品和包装。

亚型:

- HIPS (标准)

- 高密度聚苯乙烯(回收)

聚对苯二甲酸丁二醇酯

PBT 是一种热塑性工程聚合物,以其优异的机械性能和耐化学性著称。它常用于汽车和电气应用领域。

亚型:

- PBT(标准)

- PBT(增强型)

聚酰胺-酰亚胺

PAI 是一种高性能热塑性塑料,具有出色的热稳定性和机械性能。它可用于高温应用和航空航天部件。

亚型:

- PAI (标准)

- PAI (已填补)

高速钢

M2 是一种高速钢,以其高硬度、耐磨性和在高温下保持硬度的能力而著称。它常用于切削工具和钻头。

亚型:

- M2(标准)

- M2(涂层)

高速钢

高速钢是一种高性能工具钢,以能够在不降低硬度的情况下高速切削而著称。它广泛用于制造切削工具。

亚型:

- 高速钢(标准)

- 高速钢(涂层)

聚醚醚酮

PEEK 是一种高性能热塑性塑料,以其出色的耐化学性和热稳定性而著称。它可用于航空航天和医疗设备等专业应用领域。

亚型:

- 聚醚醚酮(标准)

- 聚醚醚酮(增强型)

聚甲基丙烯酸甲酯

PMMA 是一种透明的热塑性塑料,以其透明度和抗紫外线性能著称。在各种应用中,它通常被用作玻璃的轻质替代品。

亚型:

- 聚甲基丙烯酸甲酯(标准)

- 聚甲基丙烯酸甲酯(耐冲击)

聚四氟乙烯(特氟龙)

聚四氟乙烯是一种高性能含氟聚合物,以其不粘性和耐化学性著称。它广泛用于涂层、密封件和垫圈。

亚型:

- 聚四氟乙烯(标准)

- 聚四氟乙烯(填充)

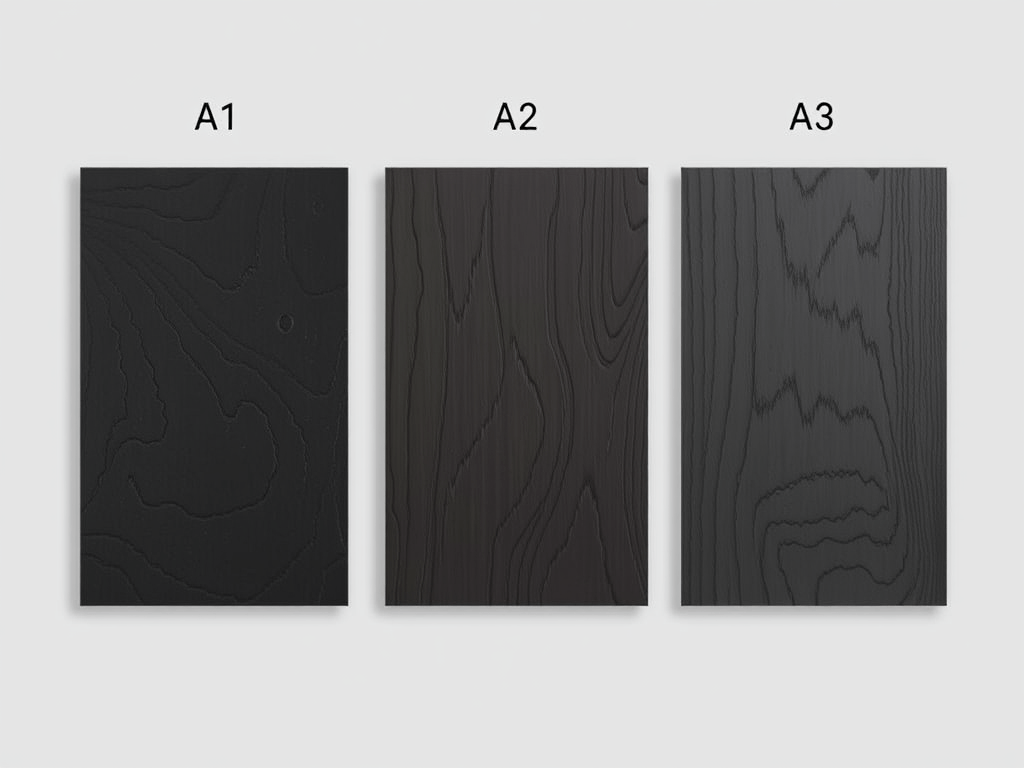

A1、A2、A3

光泽

表面光滑,没有明显的瑕疵,但允许有细小的划痕和痕迹。

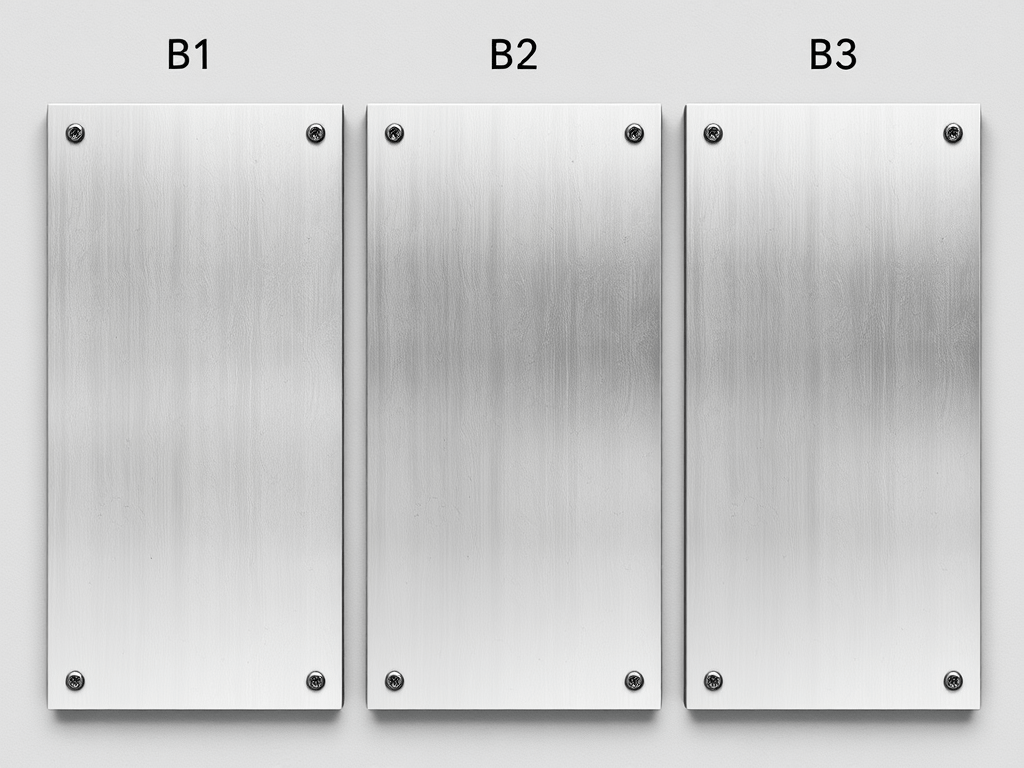

B1、B2、B3

半光泽

表面平整,无明显瑕疵,但轻微的划痕和斑点也是可以接受的。

C1、C2、C3

马特

表面为哑光,略有纹理,但不影响功能。

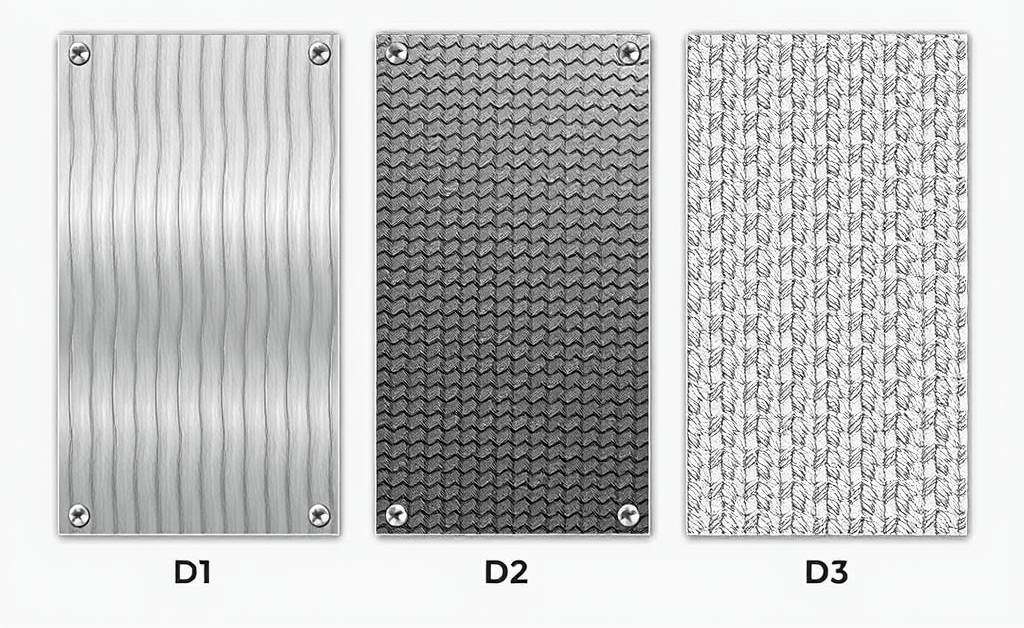

D1、D2、D3

纹理

针对防滑和耐用性等特定需求,...

图片

等级

饰面

说明

我们提供的表面处理类型

We offer a variety of surface finishes tailored to your needs, including polished, anodized, bead blasted, and coated options. We prioritize customer choice, ensuring that your products not only look great but also perform excellently. Contact us today to find the perfect finish for your project!

要求报价?

请求在线报价?

了解 SSP

What Is Precision Metal Stamping? A Beginner’s Guide to Sheet Metal Manufacturing

SSP is well known Stamping die manufacturing services provider. ..了解更多