Tooling Development Process

SSP TOOL DEVELOPMENT PROCESS : Ensuring high quality and user needs Once an order for

To guarantee that the products will reach their destination in ideal shape, and without a single damages, shipping tools—particularly heavy steel precision tooling—need to be carefully planned and executed. Inappropriate handling during air or sea transit can cause damage, delays, or regulatory problems, and precision tooling frequently weighs between 50 kg and 1000 kg. Here is a thorough guide with detailed instructions to help you transport your tools safely and effectively

Apart from to being heavy, tools—especially steel ones—can break if not packed properly.

Proper packing guarantees from SSP:

1.Protection from Damage: In order to avoid dents, scratches, or breakage, on the tools we frequently contain sharp edges or delicate parts that require cushioning.

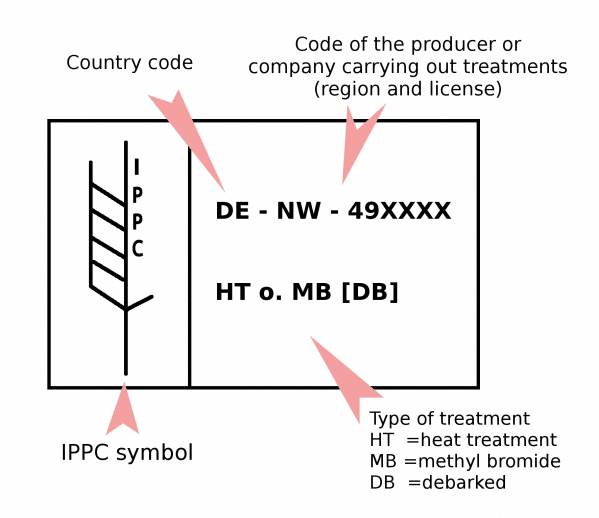

2.Regulation Compliance: Packaging for foreign exports needs to follow certain rules, like the IPPC’s (foreign Plant Protection Convention) specifications for wooden boxes.

3.Cost Effectiveness: Tools that are properly packed reduce the possibility of delays or products.

Step-by-Step Guide to Packing Tools for Shipping

Step 1: Choose the Right Wooden Box

A sturdy wooden box is essential for heavy tools. For international shipping, ensure the box is compliant with IPPC standards. This involves using heat-treated wood with a certified IPPC logo. Here’s what to look for:

Step 2: Protect Sharp Edges

Tools often have sharp or pointed edges that can puncture packaging or cause injuries. Use foam or bubble wrap to cover these edges securely. This prevents damage to both the tools and the packaging. and sure the safe journey.

Step 3: Organize Spare Parts and Components

If you are shipping spare parts or additional components along with the main tool, pack them separately. Use:

Label each container clearly to make unpacking easier for the recipient.

Step 4: Add Cushioning Materials

Place the tools inside the wooden box and fill any empty spaces with cushioning materials. Options include:

The goal is to prevent the tools from shifting inside the box during transportation.

Step 5: Secure the Tools

Once the tools are placed in the box:

This step is especially important for large or heavy tools that could cause damage if they shift.

Step 6: Seal the Box

Close the wooden box and seal it properly using industrial-grade nails or screws. Reinforce the edges with metal brackets if necessary for added durability. Finally, wrap the box with stretch film or plastic wrap to protect it from moisture and dust.

Conclusion

Shipping heavy tools across the country or overseas requires attention to detail and adherence to proper packing methods. By following the steps outlined above, you can ensure your tools are well-protected, comply with regulations, and arrive at their destination safely.

Visit SS Precision for reliable precision tooling and expert shipping advice. We specialize in high-quality tools and offer comprehensive solutions for all your shipping needs. With years of experience, our team ensures your tools are shipped safely and efficiently every time.

SSP TOOL DEVELOPMENT PROCESS : Ensuring high quality and user needs Once an order for

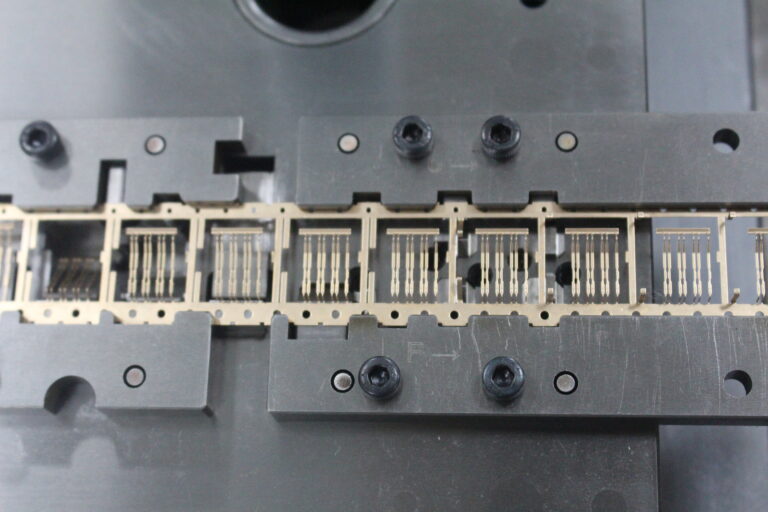

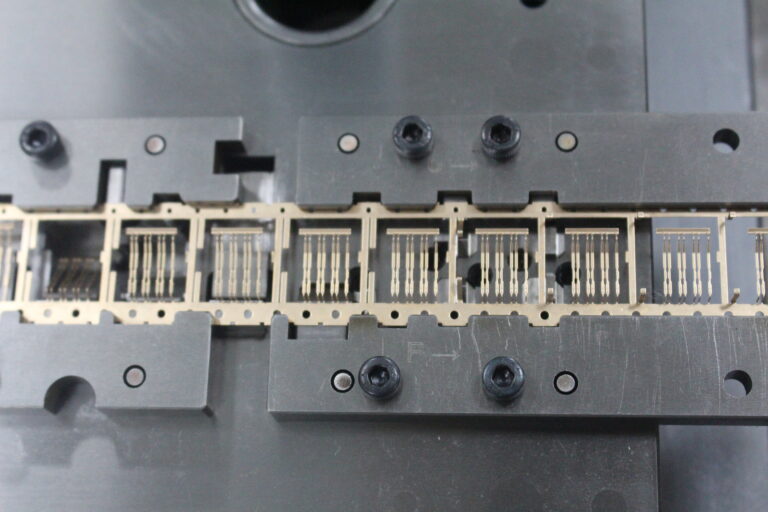

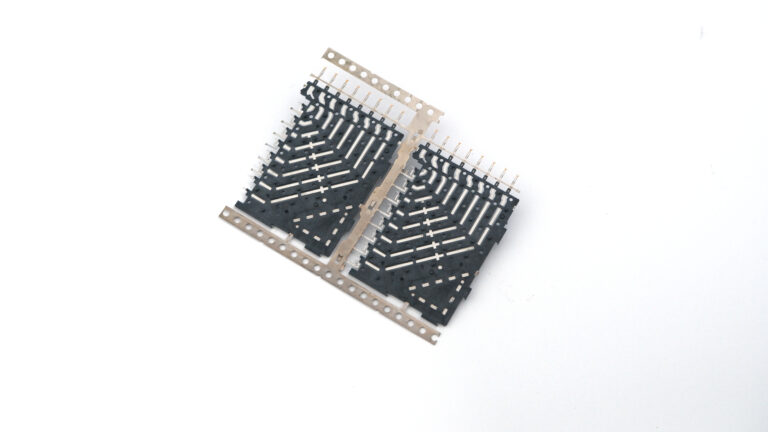

A fantastic work done… High-speed backplane connector terminals tool, very tight tolerance(+/-0.02mm),very limited lead time,

SSP is a Chinese leading company in the manufacture of tooling spare parts, stamping die, injection mould, machined parts and prototype samples used in many different fields of the industry .