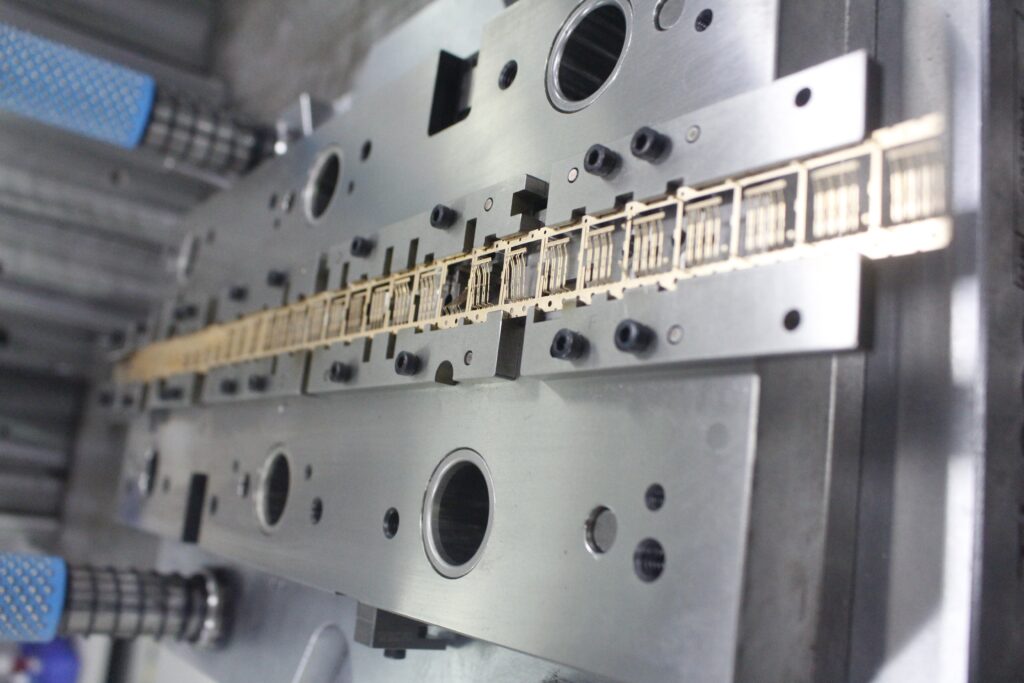

Stamping production

We have developed unique expertise and experience in creating complex, highly precise products, particularly in connectors, switches, and sensors.

Expertise: High-precision stamping and busbar parts.

Experience: Solid background in press fit terminal manufacturing, including Elo pins and multispring pins.Integrated Processes: Capability to incorporate thread forming, rivet feeding, and contact riveting in tooling.

Metal Strip Thickness: Handles thickness from 0.05 to 5 mm.

Press Force: Range from 40 to 160 tons.

Stamping Speed: Up to 1,000 strokes per minute.

Injection molding Production

Tailor-Made Solutions: Dedicated to providing high-performance solutions requiring extreme precision and micro tolerances.

Equipment: Operate 15 injection molding machines, with capacities ranging from 30 to 200 tons.

Specialty: Expertise in connecting stamped parts to plastic.

Composite Parts: Offer plastic-metal composite parts through insert molding and overmolding to reduce interfaces and enhance quality and cost efficiency.

At the heart of our business is a commitment to providing cutting-edge solutions in progressive die stamping, progressive die and stamping, and precision injection molding. We understand that every project is unique, which is why we offer custom metal stamping dies designed to meet your specific needs, ensuring unmatched durability, efficiency, and performance. Our team works closely with you to optimize every aspect of your production process, from design to delivery, ensuring your products meet the highest quality standards. Whether you’re looking to streamline your operations, reduce costs, or enhance product performance, we are here to provide reliable, innovative manufacturing solutions that help you stay ahead of the competition. Partner with us, and experience a seamless process where your vision meets precision and excellence.

Learn about SSP

How to order and Communicate with SSP.

In the fast-paced world of precision manufacturing, effective communication and streamlined ordering processes are vital for Learn more

Tooling Development Process

Once an order for stamping die or injection mould is fixed, The below is a typical tooling Learn more

High-speed backplane connector terminals tool

High-speed backplane connector terminals ..Learn more