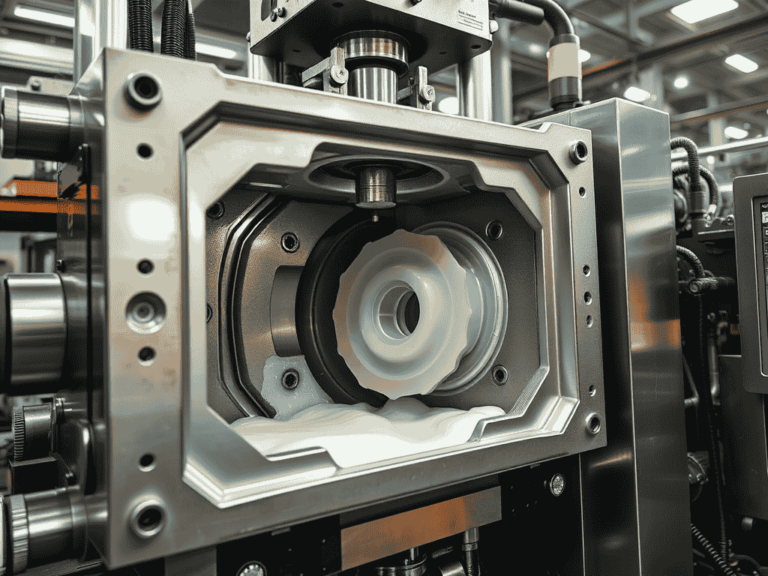

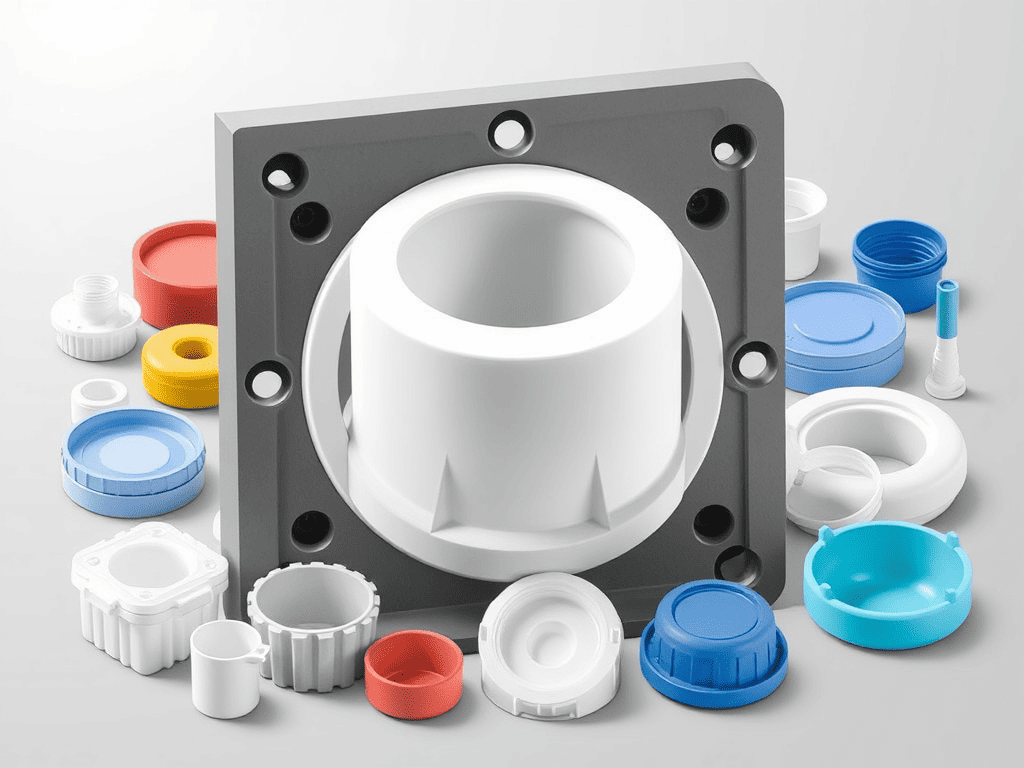

INJECTION MOLDING SERVICES

As a leading injection molder and one of the top injection molding companies, We pride ourselves on being the best injection molding company for quality and reliability. Our advanced technology and skilled craftsmanship deliver precision-molded components with fast turnaround times and competitive pricing.

From prototype development to full-scale production, our injection molder expertise ensures your projects meet the highest standards. Partner with us for exceptional results—contact us today to discuss your custom molding needs.

- Custom injection molder

- 25+ Surface Finishes, 50+ Materials to Choose

- One-Stop Service, Online molding Solutions

- ISO 9001: Certified

About our Injection molding company

We specialize in high-precision injection molding, We are renowned for providing cost-effective, durable, and scalable solutions for a wide range of industries. Whether you need rapid prototyping, low-volume production, or large-scale manufacturing, our advanced technology ensures consistent quality, tight tolerances, and superior performance for every part we produce.

With a state-of-the-art facility, expert engineering team, and cutting-edge molding techniques, As the best injection molder we help you streamline production, reduce costs, and bring complex product designs to life with exceptional precision.

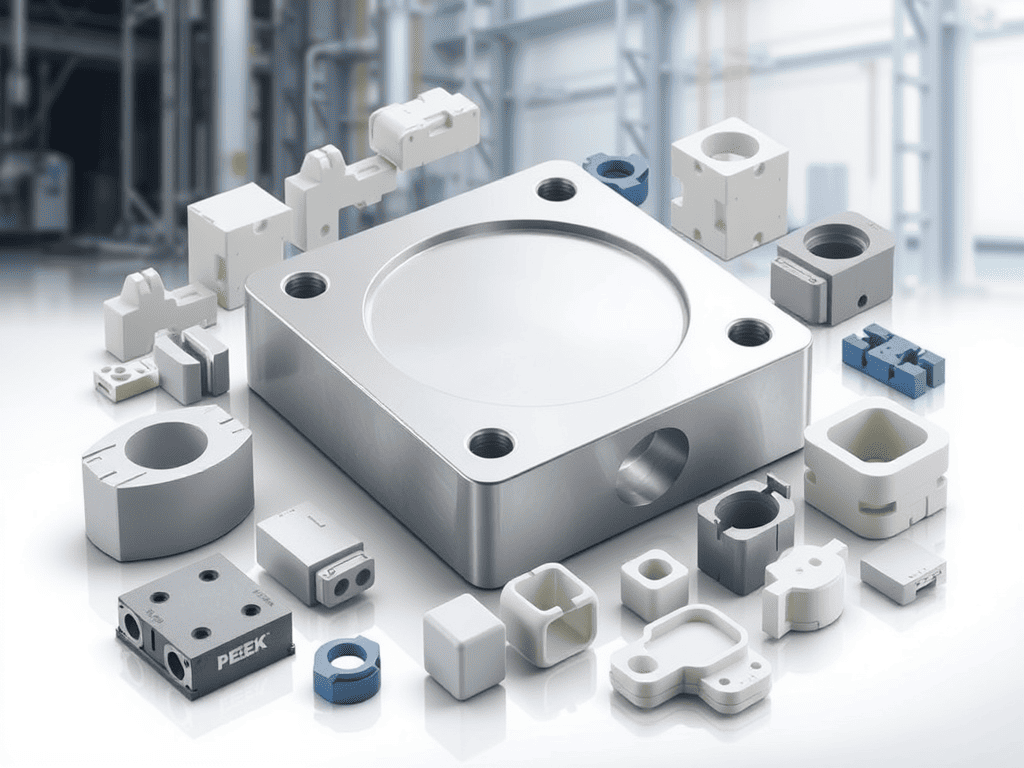

We as Injection molder

Custom Injection Molder: Tailored solutions for unique specifications in plastic injection molding.

High-Precision Molding: Accurate complex designs from the best injection molding company.

Engineering-Grade Plastics: Using materials like PEEK, Ultem, Nylon, and ABS.

Multi-Shot & Overmolding: Enhanced functionality with multiple materials.

Rapid Prototyping: Quick turnaround for design validation.

High-Volume Manufacturing: Scalable solutions with consistent quality.

Cleanroom Molding: Meets strict medical industry standards.

Insert Molding: Integrating metal and electronic components for durability.

Gas-Assisted Molding: Lightweight, strong parts with material efficiency.

High-Precision & Tight-Tolerance Molding

At SSP, our plastic injection molding services prioritize high precision and tight tolerances, essential for producing components with exact dimensions and superior quality. This service is critical for industries such as aerospace, automotive, and electronics, ensuring compliance with strict specifications for optimal performance as a trusted injection molder.

Key Benefits:

- Exact Specifications: Perfect fit for every component.

- Enhanced Performance: Improved functionality and reliability.

- Material Versatility: Compatible with various materials.

- Reduced Waste: Minimizes material waste and costs.

- Custom Solutions: Tailored to specific industry needs.

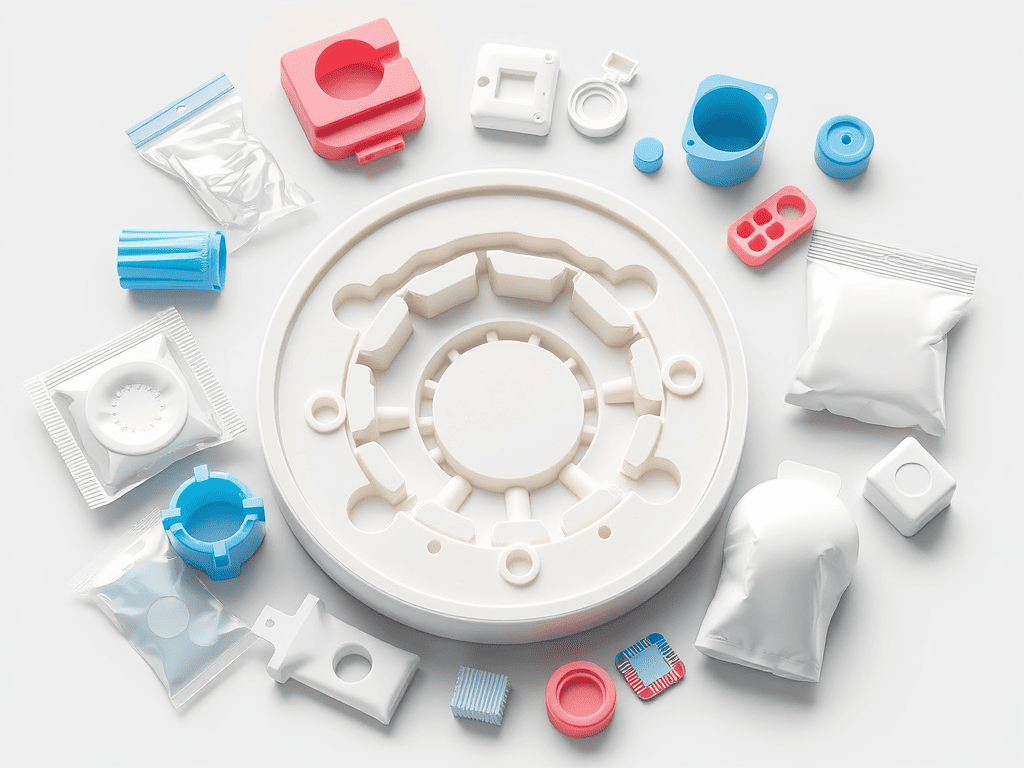

Multi-Shot & Two-Shot Plastic injection Molding

At SSP, we specialize in plastic injection molding, including multi-shot and two-shot techniques.

Multi-shot molding involves injecting different materials or colors into a single mold to create complex parts in one process. This technique allows for the seamless integration of various textures and functionalities, enhancing the overall design.

Two-shot molding specifically uses two different materials injected in sequence to create a single part with distinct properties, such as soft-touch surfaces combined with rigid sections.

These advanced methods enable us to produce high-quality, multi-material components ideal for industries like automotive and consumer products, delivering both aesthetic appeal and improved performance.

Choose SSP for innovative plastic injection molding solutions and elevate your product quality!

As a Injection molder

As the best injection molding company, we specialize in custom injection molding, performing a precise manufacturing process that creates tailored plastic parts for various industries, including automotive and medical. At SSP, we ensure high-quality components that meet exact specifications and enhance performance.

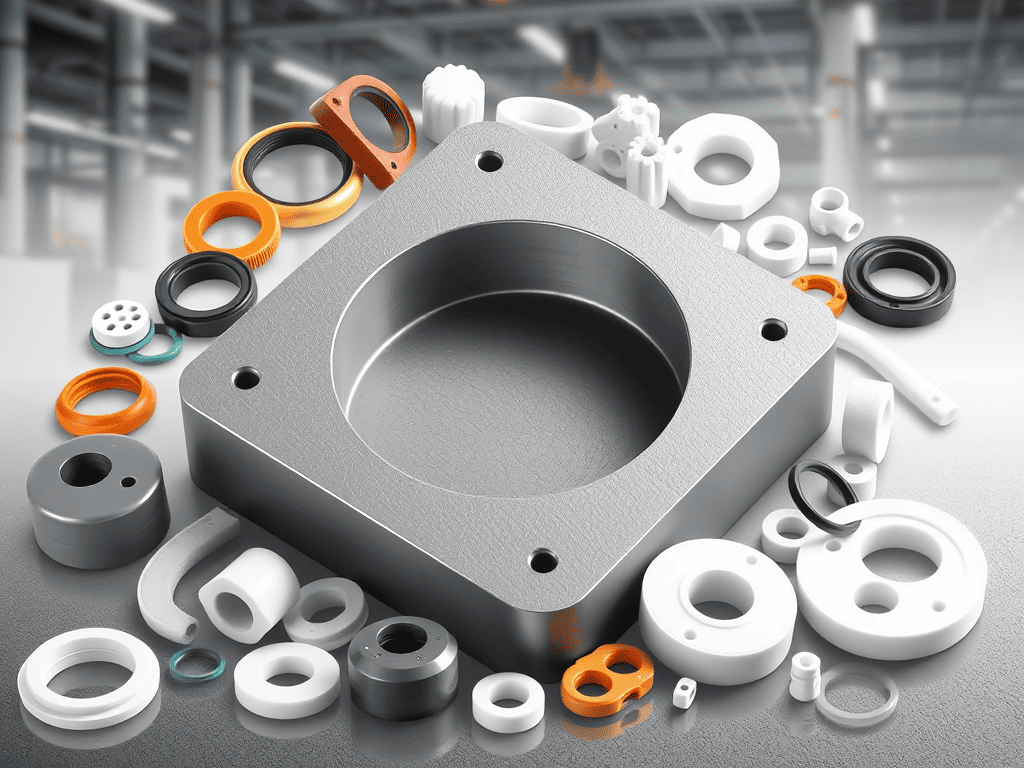

Over Molding & Insert Molding

SSP stands out among injection molding companies with our expertise in over molding and insert molding, designed to boost the functionality and durability of plastic components. Over molding involves adding soft-touch materials, while insert molding integrates additional components directly into the plastic.

These techniques deliver innovative, multi-functional solutions for a wide range of industries. Trust SSP for your advanced molding needs!

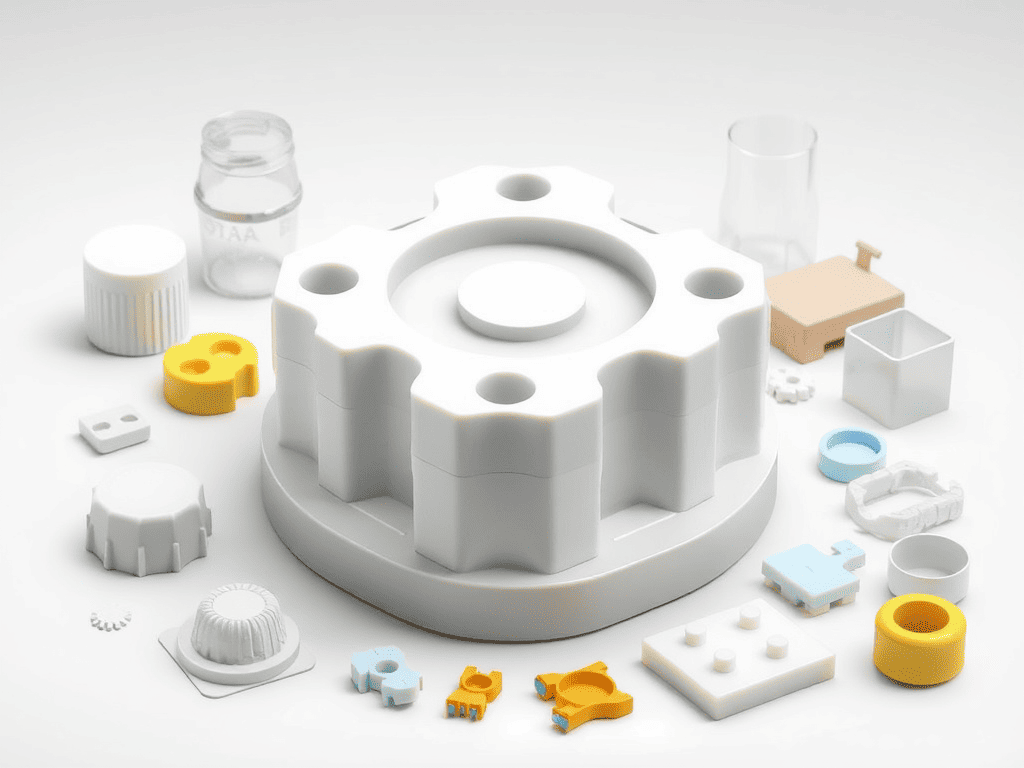

Some categories we offer for INJECTION MOLDING

SSP provides high-quality prototype samples FOR INJECTION MOLDING tailored to your needs WITH COLABORATION WITH MW+. Experience precision and rapid turnaround with the best injection molding company, enabling you to evaluate designs before full production. Bring your ideas to life with our expert craftsmanship as a leading injection molder!

Minimum Order

Quantity (MOQ)

We prioritize your needs with a flexible minimum order, perfect for small or prototype requests.

Total Parts

Manufactured

This metric shows the total number of parts produced, highlighting our production efficiency.

Design

Variety

Choose from over 6000 unique designs, ensuring diverse options for every preference.

Shipping

Availability

We offer worldwide shipping, making our products accessible to customers around the globe.

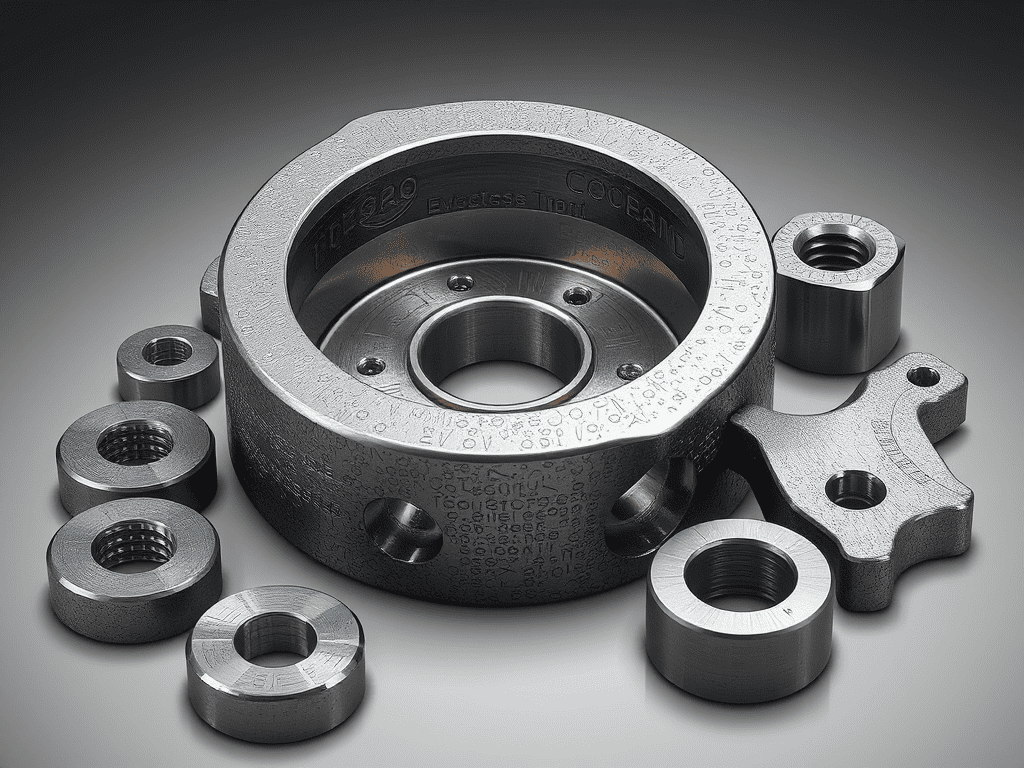

Checkout Our molding Products

Discover how we blend creativity and precision in our manufacturing process. Using advanced technology and skilled craftsmanship on our products, we transform raw materials into high-quality products that exceed expectations.

Sign Up (Initial Information)

We safeguard customer confidentiality by only emailing about orders and services, never sharing personal information or sending spam.

- Name

- Company Name

Fill In The Order Details

You can request quotes for various quantities and materials. If you don’t have a design file or a complete project concept, please reach out to us at rockie.liu@ssprecision.com.cn , otherwise submit.

- Design Files

- Materials

- Surface Finishes

Manage Order

Once you Submit order, you can check its progress on the order management page. Generally, our quotation will be updated in 24 hours and we will notify you by email.

- 24 Hours Quote

- Email Notification

- Progress Follow-Up

Order Confirm

The confirmation should include order details, such as the part name or number, quantity ordered, and the requested delivery date.

- Production Cost

- Payment Information

- Shipping Information

How to get an INJECTION MOLDING Quote Online?

Our Manufacturing Processes

Our plastic injection molding services are highly effective for high-volume production of plastic parts. This technique involves shaping plastic materials using a mold to create precision components, which are then ejected after forming. This method ensures efficiency, accuracy, and consistent quality in every finished part. That’s how we become the best injection molder.

INJECTION MOLDING (The Materials We Use)

Tool Steel (high wear resistance)

D3 is a high carbon, high chromium tool steel known for its excellent wear resistance and ability to maintain a sharp edge. It is commonly used for cutting tools, dies, and industrial applications requiring high durability.

Subtypes:

- D3 (Standard)

- D3 Cold Work Tool Steel

Pre-Hardened Tool Steel

P21 is a pre-hardened tool steel that offers good machinability and wear resistance. It is ideal for making molds and dies, as it doesn’t require extensive heat treatment.

Subtypes:

- P21 (Standard)

- P21+ (Improved)

Hot Work Tool Steel

H11 is a hot work tool steel known for its toughness and thermal fatigue resistance. It is used in applications involving high temperatures, such as die casting and forging.

Subtypes:

- H11 (Standard)

- H11A (Modified for improved toughness)

Polyoxymethylene (Acetal)

POM is a high-performance engineering thermoplastic known for its low friction, high stiffness, and excellent dimensional stability. It’s widely used in precision parts and mechanical components.

Subtypes:

- POM-C (Copolymer)

- POM-H (Homopolymer)

Polyamide (Nylon)

PA is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Subtypes:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige (Natural)

- PA66 (Nylon) Black

Polypropylene

PP is a lightweight, durable thermoplastic known for its chemical resistance and versatility. It is widely used in packaging, automotive parts, and consumer goods.

Subtypes:

- PP Homopolymer

- PP Copolymer

High-Density Polyethylene

HDPE is a strong and versatile thermoplastic known for its high strength-to-density ratio. It is commonly used in containers, piping, and plastic bottles.

Subtypes:

- HDPE (Standard)

- HDPE (Recycled)

Low-Density Polyethylene

LDPE is a flexible and durable thermoplastic known for its low density and high chemical resistance. It is often used in packaging films and bags.

Subtypes:

- LDPE (Standard)

- LDPE (Recycled)

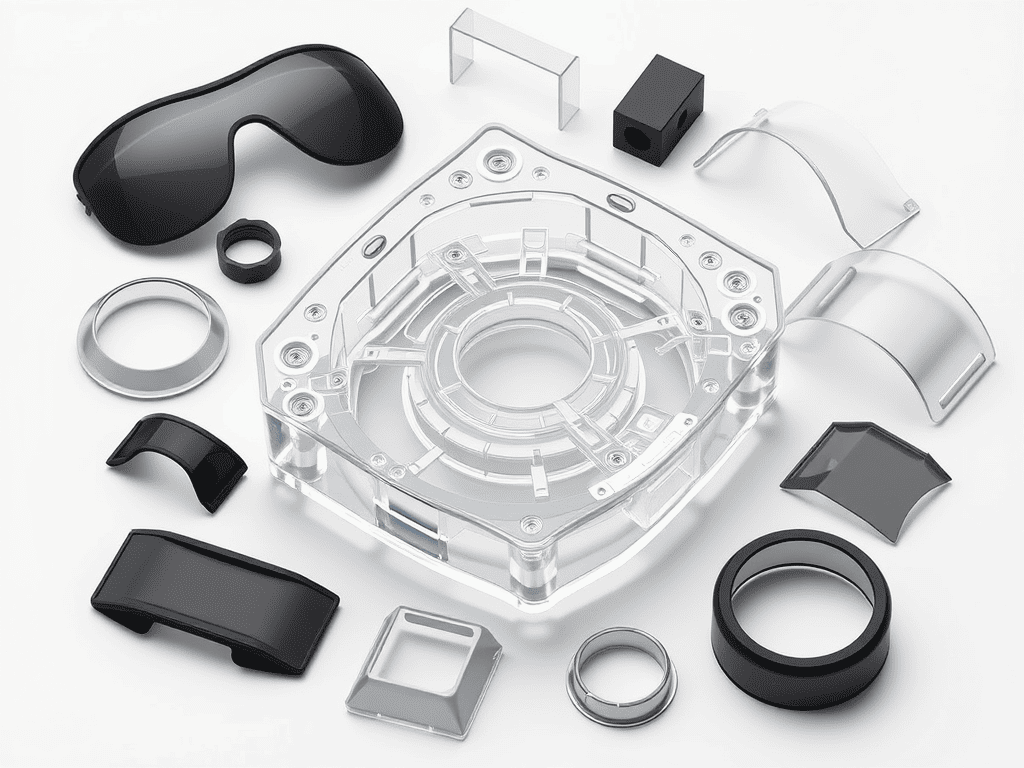

Polycarbonate

PC is a strong, impact-resistant thermoplastic known for its clarity and heat resistance. It is commonly used in eyewear lenses, safety equipment, and electronic components.

Subtypes:

- PC (Standard)

- PC (Flame Retardant)

High-Impact Polystyrene

HIPS is a tough and impact-resistant thermoplastic known for its ease of processing and good surface finish. It is commonly used in consumer products and packaging.

Subtypes:

- HIPS (Standard)

- HIPS (Recycled)

Polybutylene Terephthalate

PBT is a thermoplastic engineering polymer known for its excellent mechanical properties and chemical resistance. It is often used in automotive and electrical applications.

Subtypes:

- PBT (Standard)

- PBT (Reinforced)

Polyamide-imide

PAI is a high-performance thermoplastic known for its excellent thermal stability and mechanical properties. It is used in high-temperature applications and aerospace components.

Subtypes:

- PAI (Standard)

- PAI (Filled)

High-Speed Steel

M2 is a high-speed steel known for its high hardness, wear resistance, and ability to retain hardness at elevated temperatures. It is commonly used for cutting tools and drills.

Subtypes:

- M2 (Standard)

- M2 (Coated)

High-Speed Steel

HSS is a high-performance tool steel known for its ability to cut at high speeds without losing hardness. It is widely used in manufacturing cutting tools.

Subtypes:

- HSS (Standard)

- HSS (Coated)

Polyether Ether Ketone

PEEK is a high-performance thermoplastic known for its excellent chemical resistance and thermal stability. It is used in specialized applications such as aerospace and medical devices.

Subtypes:

- PEEK (Standard)

- PEEK (Reinforced)

Polymethyl Methacrylate

PMMA is a transparent thermoplastic known for its clarity and UV resistance. It is commonly used as a lightweight alternative to glass in various applications.

Subtypes:

- PMMA (Standard)

- PMMA (Impact Resistant)

Polytetrafluoroethylene (Teflon)

PTFE is a high-performance fluoropolymer known for its non-stick properties and chemical resistance. It is widely used in coatings, seals, and gaskets.

Subtypes:

- PTFE (Standard)

- PTFE (Filled)

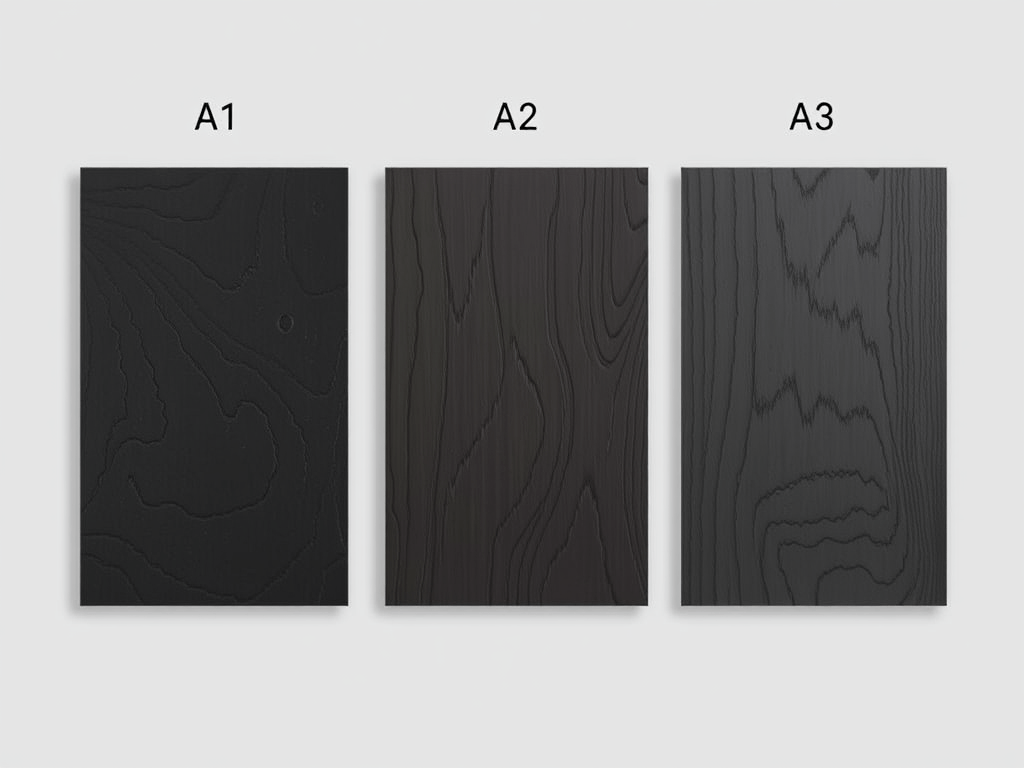

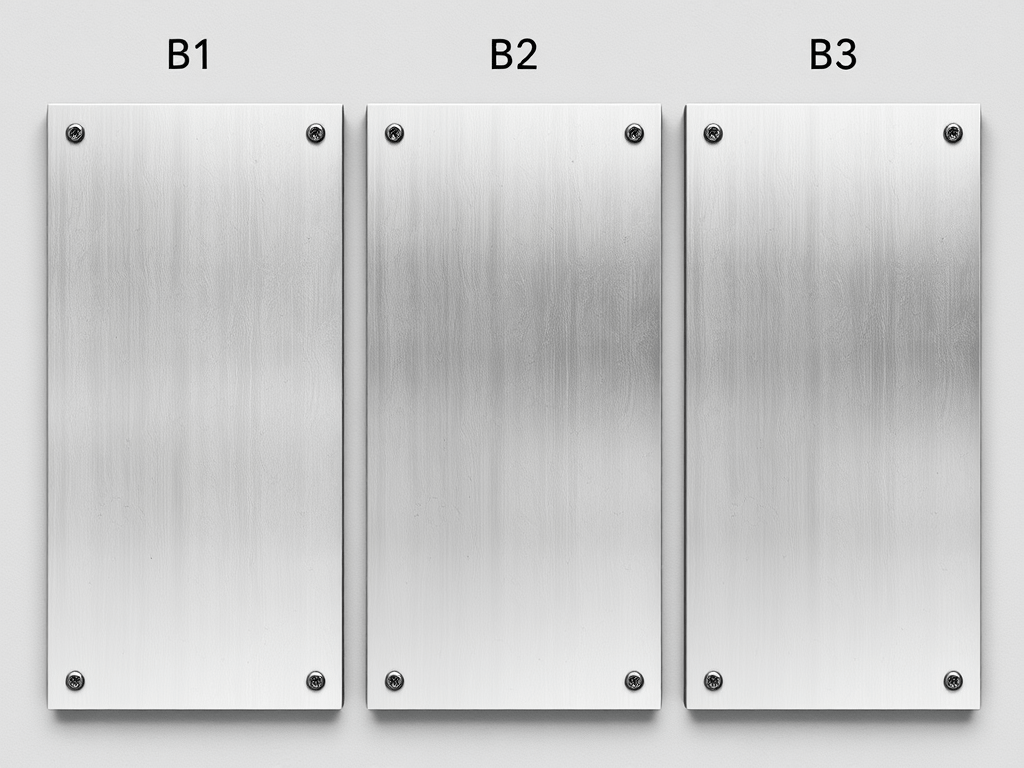

A1, A2, A3

Glossy

The surface is sleek and devoid of noticeable flaws, although small scratches and marks are permissible.

B1, B2, B3

Semi-glossy

The surface is even and free of significant imperfections, though minor scratches and spots are acceptable.

C1, C2, C3

Matt

The surface is matte and slightly textured, but it does not impact functionality.

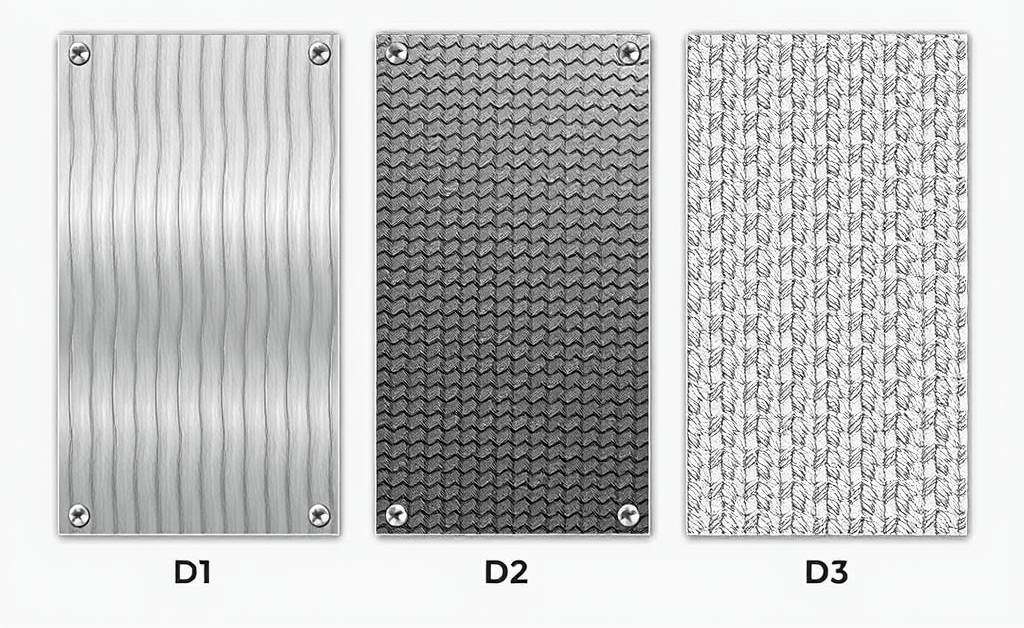

D1, D2, D3

Textured

For specific needs, such as slip resistance and durability, …

Pictures

Grade

Finishes

Descriptions

THE TYPES OF SURFACE FINISHES WE OFFER

we offer a variety of surface finishes tailored to your needs, including polished, anodized, bead blasted, and coated options for our INJECTION MOLDING services. We prioritize customer choice, ensuring that your products not only look great but also perform excellently. Contact us today to find the perfect finish for your project!

Request a Quote?

Request a Online Quote?

Learn about SSP

Injection Mold Cooling Time to Cut Costs and Improve

Have you ever wondered why two injection molding companies Learn more

Costs of Cheap Injection Molds

Many companies chase cheap injection molding to cut budgets, but Learn more